Related Post

Can Low-throughput Focused-ultrasonicators Meet High-Repeatability Needs?

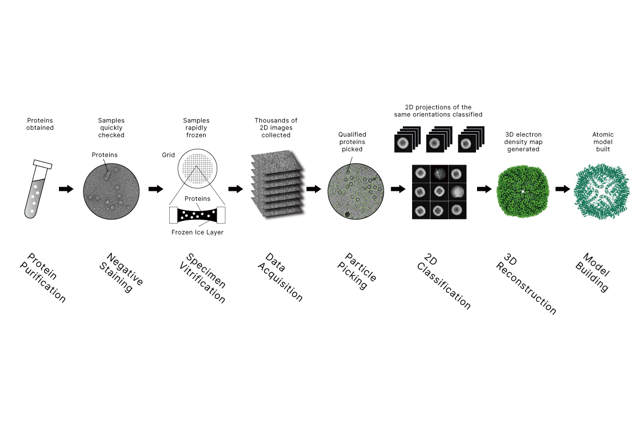

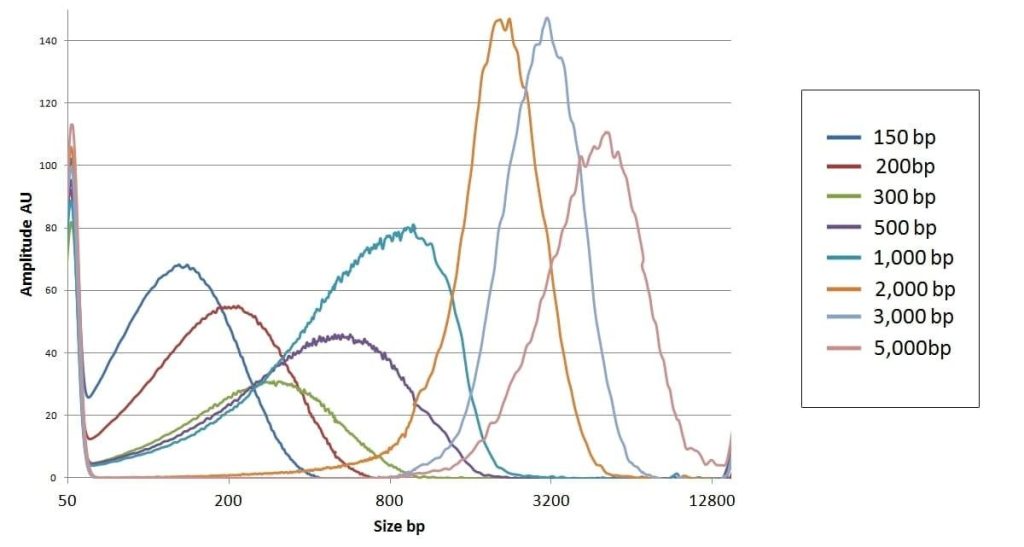

2025-11-20Low-throughput Focused-ultrasonicators use concentrated acoustic energy to process small sets of samples with tight control. They help shear DNA, lyse cells and tissues, and prepare FFPE or microbial samples. These tools appear across global genomics and proteomics labs. They support landmark next-generation sequencing, epigenomics mapping, and biomarker discovery programs at leading institutes and consortia. The promise is simple: clean energy delivery, minimal contamination risk, and stable temperature control. The reality can be different when workloads grow and operators change. So, can Low-throughput Focused-ultrasonicators truly deliver high repeatability in real labs? Let’s test that claim next.

(RNA & DNA Shearing For NGS | Covaris)

What High-Repeatability Really Means In The Lab

High-repeatability is not a buzzword. It means the same sample type, processed across different runs, users, and days, yields near-identical fragment sizes, recovery, and QC metrics. In NGS library prep and advanced proteomics, small drifts can cascade into costly rework or failed sequencing.

✅ Where Low-throughput Focused-ultrasonicators Fall Short

Many instruments marketed for precision still leave gaps when workloads grow or samples vary.

• Frequent manual setup steps introduce user-to-user variability.

• Single-sample or dual-sample limits create long queues and time pressure.

• Thermal drift during sonication alters fragment profiles and enzyme performance.

• Probe contact or indirect water paths raise contamination risk.

• Sparse run records make it hard to audit parameters when QC flags appear.

When these factors stack up, “repeatable enough” stops being enough – especially for regulated labs or production NGS pipelines.

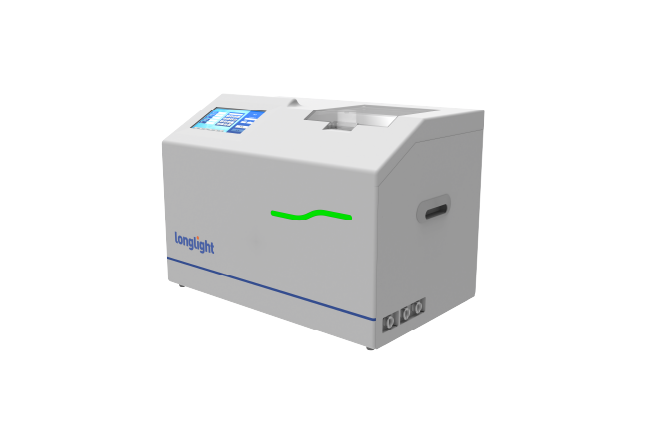

How Longlight Technology Solves The Low-Throughput Bottleneck

Our engineering brief was simple: deliver the control that Low-throughput Focused-ultrasonicators promise, but at scale, without adding complexity for scientists. The result is a multi-channel, focused ultrasound platform with 16 sample well positions that processes true batches while preserving per-sample control.

1) Focused Energy, Non-Contact Control

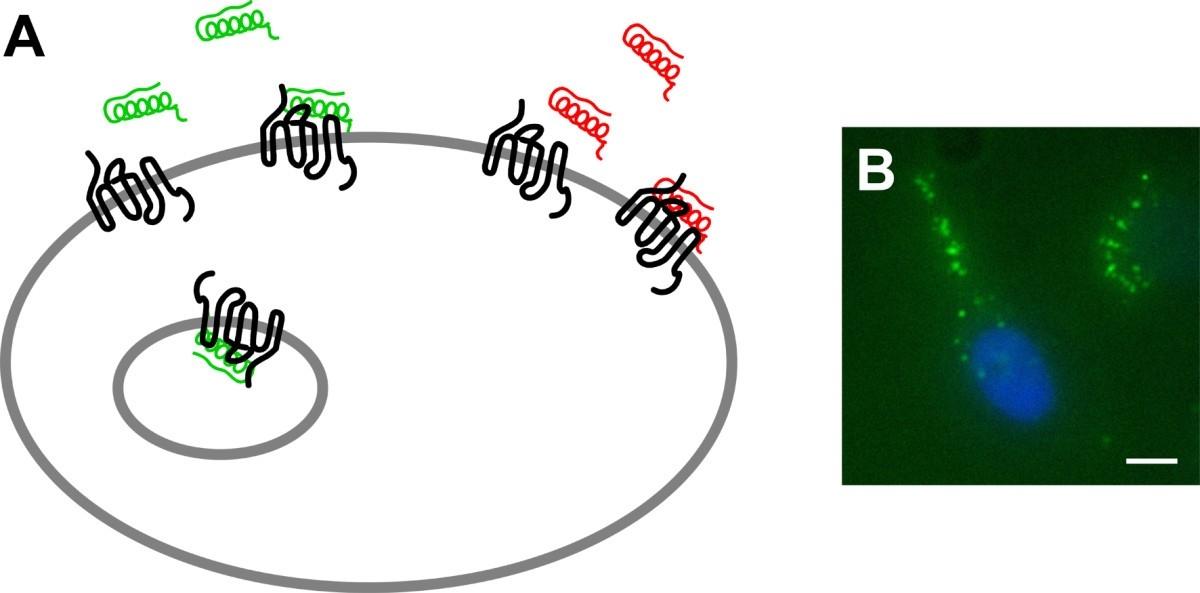

We employ advanced confocal acoustics to focus high-frequency, short-wavelength sound directly on the sample. Energy couples through an acoustic medium – no probe contact – so precious DNA, RNA, and proteins avoid the contamination paths common to traditional sonic systems. Quiet operation means no extra sound-insulation box; you place it where the work happens.

In practice, this design gives you two powerful modes:

- Free-sample mode for 1 – 16 samples, each with independent power, duty cycle, and time – ideal for mixed inputs, tricky matrices, or pilot optimization.

- Batch mode for rapid one-click runs on similar samples – load parameters once, run many.

The benefit is not only speed; it’s tighter control. Complex cohorts – FFPE, tough microbes, viscous lysates – get tailored energy without breaking your schedule.

2) Temperature And Traceability, Built In

Thermal management is a hidden variable that ruins repeatability. Our true low-temperature, constant-temperature processing uses high-sensitivity sensing and closed-loop control to keep the sample zone steady throughout sonication. Fragment sizes remain consistent, enzymes stay happy, and downstream cleanup behaves as expected.

Traceability is equally critical. Every run logs the who/what/when/parameters so processing information is retrievable at any time, enabling real audits and faster root-cause analysis. Automatic drainage with a level sensor and early-warning system protects against overflow and keeps benches clean. And because the system has its own operating software, you don’t lose space or time cabling to an external PC.

✅ Key Outcomes You Can Expect

- More consistent fragment profiles for genome fragmentation and chromatin work.

- Lower contamination risk thanks to non-contact energy delivery.

- Higher daily throughput by running up to 16 samples without babysitting.

- Cleaner records for compliance and method transfer across sites.

Can They Meet High-Repeatability Needs? A Practical Yes

If your definition of repeatability includes scalable capacity, strict temperature control, non-contact processing, and auditable records, then the answer is yes – but you need an instrument that resolves the classic low-throughput pain points, not one that simply rebrands them.

✅ Real-World Use Cases

Our focused ultrasound platform is built for modern sample prep:

• Genome fragmentation for NGS where fragment length distribution must hold steady across runs.

• Difficult cell and tissue disruption for nucleic acid or protein extraction without overheating.

• FFPE deparaffinization that benefits from controlled acoustics and stable temperature.

• Microorganisms and filamentous fungi where robust lysis is needed without cross-contamination risks.

• General genomics and proteomics workflows that demand standardized results at scale.

❓ Why This Matters For Your Pipeline?

Low-throughput Focused-ultrasonicators can be precise in isolation yet fail under real laboratory pressure – mixed batches, varied operators, and weekly method updates. By combining focused, non-contact energy, tight temperature regulation, 1 – 16 flexible lanes, and one-click batch processing, Longlight Technology delivers repeatability that survives actual production conditions. You gain both control and capacity, so performance no longer depends on one expert user or a quiet afternoon.

Call To Action

Ready to see how focused, non-contact acoustics and true temperature control change your results? Talk to Longlight Technology for a live demo, sample-to-report evaluation, or a side-by-side comparison against your current Low-throughput Focused-ultrasonicators. Let’s turn repeatability into your laboratory’s default setting.