Related Post

Why Your Magnetic Separation System Struggles in Multi-Liter Batch Processing

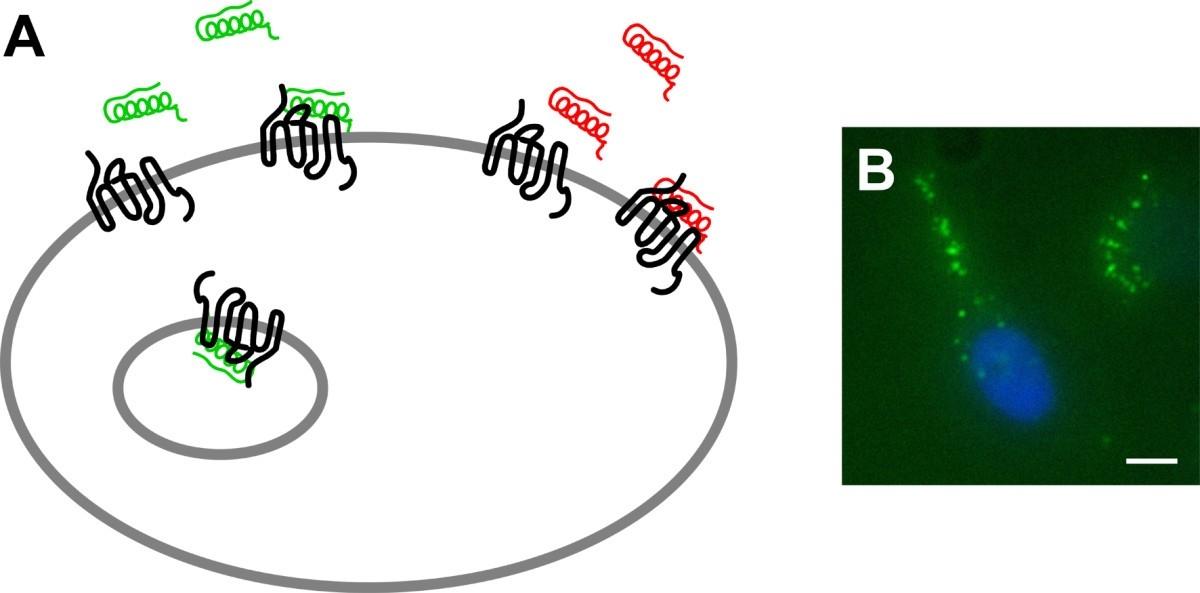

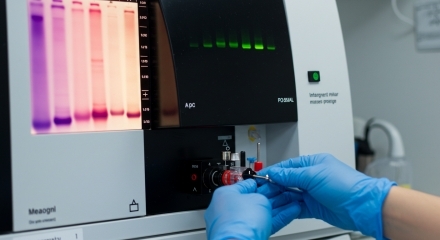

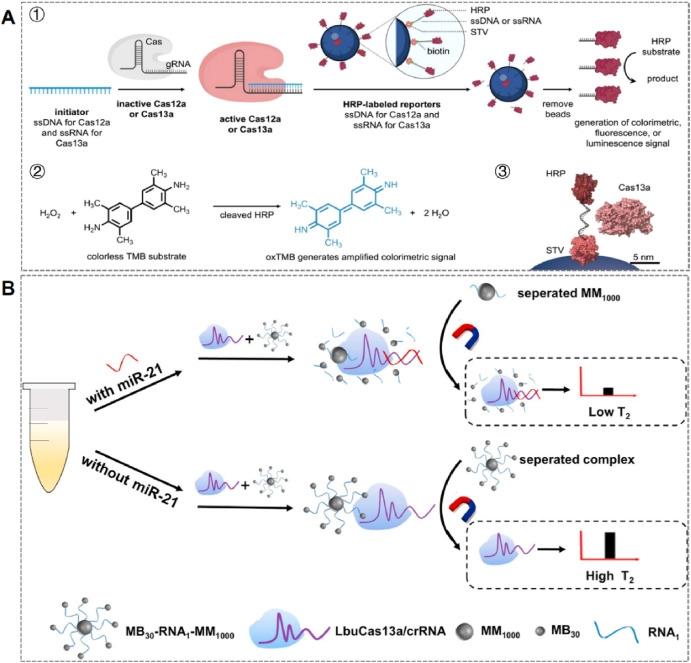

2025-11-14A Magnetic Separation System uses controlled magnetic fields to capture and release functionalized beads. It isolates targets like DNA, proteins, and cells. It often replaces centrifugation. It powers workflows in diagnostics, biomanufacturing, and synthetic biology. It supports biocatalysis and sample cleanup. International teams report strong results in single-cell research and high-throughput nucleic acid prep. Leading labs use it in CRISPR screens and pandemic-era testing. Yet scale changes everything. Volumes rise. Losses creep in. Variability grows. What fails first at multi-liter scale – and how do you fix it? Keep reading.

(Magnetic particles-integrated CRISPR/Cas systems for biosensing – ScienceDirect)

The Real Reasons Multi-Liter Batches Go Wrong

When a Magnetic Separation System moves from bench scale to several liters per batch, small inefficiencies turn into big losses. Magnetic beads no longer move as a compact front. Flow paths change, dead zones appear, and operators compensate with longer hold times. That raises the risk of bead aggregation and variable yields. Inconsistent magnetic field exposure across a wider working area causes uneven capture; some beads immobilize fast, others drift in suspension, and valuable targets ride along into waste.

Scale also exposes process fragility. Minor vortexing during mixing becomes shear stress that chips beads. Longer cycles invite temperature drift, which alters viscosity and separation kinetics. Safety is another pain point. Traditional large magnets can be awkward to handle at scale, creating risks during setup, cleaning, and changeover. Each of these issues nudges costs upward – more raw materials, more rework, more quality checks – and erodes throughput right when demand is rising.

✅ Hidden Pain Points In Scale-Up

• Uniform magnetic field coverage is hard to maintain in wider vessels, leading to bead piles and channeling.

• Bead loss rises during transfers and wash steps as volumes grow and contact surfaces multiply.

• Long separation times create variability; operators “wait and see,” which hurts reproducibility.

• Handling large magnets without protection invites safety events and downtime.

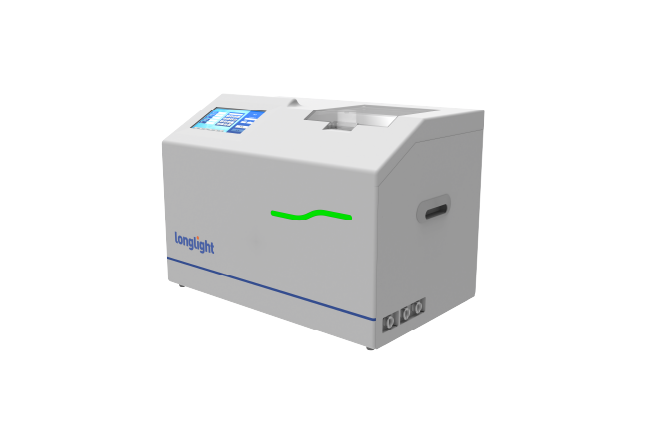

How Longlight Technology Stabilizes Multi-Liter Separation

At Longlight Technology, we design the Magnetic Separation System around one goal: keep every bead in the same force field environment, across the entire working zone, for every batch. A uniform and stable magnetic field prevents local hotspots that cause accumulation. This simple principle pays off – beads immobilize evenly, release on cue, and stop forming aggregates that steal yield.

Our systems are built for scale-up from milliliters to tens of liters, including custom volumes, so process parameters track cleanly from R&D to GMP floors. Real-time monitoring helps operators see separation progress as it happens. Instead of waiting for a timer, teams react to signals – immobilization status, flow clarity, and step-to-step consistency – reducing variability and catching issues before they cascade.

We also streamline the physical workflow. By removing centrifugation steps and enabling one-step protocols, the process shortens, and human touch points drop. Fewer transfers mean fewer losses. Purpose-built protection around the magnetic circuit reduces safety risks that come with traditional large magnets, making setup and cleaning simpler and safer.

✅ What Our Magnetic Separation System Changes

• Lower Bead Loss: Controlled immobilization and release reduce carry-over across washes.

• Consistent Results: Real-time monitoring supports reproducible separation in every run.

• Faster Batches: One-step protocols cut non-value-added time and improve throughput.

• Safer Operation: Protective design minimizes risks during handling and maintenance.

From Pilot To Production: A Practical Playbook

Moving to multi-liter batches is not just “more of the same.” It requires three practical shifts. First, treat field uniformity as a critical quality attribute. If the Magnetic Separation System generates a stable field across the full working area, you avoid the root causes of bead aggregation and inconsistent capture. Second, instrument the process. In our experience, light-touch sensing and process visualization deliver outsized gains – operators learn when the beads are truly immobilized and stop over- or under-holding steps. Third, simplify the path. Every extra transfer or spin is an opportunity for loss; a direct, centrifuge-free workflow preserves material and time.

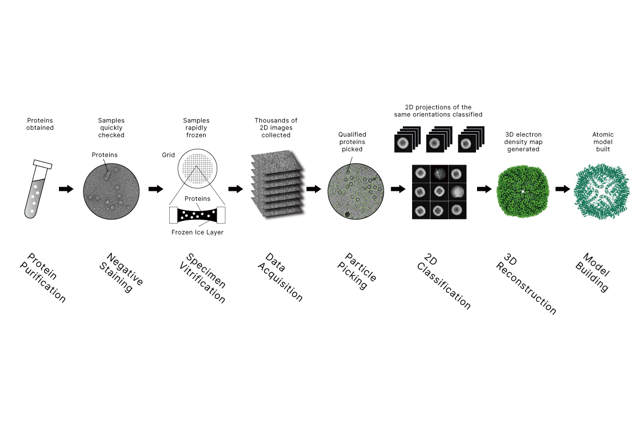

In large-scale biomagnetic separation – nucleic acid capture, protein purification, cell sorting, biocatalysis, and diagnostics – these shifts translate into clearer supernatants, tighter yield bands, and fewer surprises at release testing. Production teams reach target capacity (several liters per batch) without the usual scrap and overtime. Quality teams see a cleaner validation story because the separation is consistent by design, not by operator heroics. And EHS leads appreciate that safer magnet handling is built in, not bolted on.

✅ Where The Gains Show Up

• Yield And Purity: Even field exposure reduces co-elution and protects downstream analytics.

• Throughput: Shorter separation steps accelerate daily batch counts without sacrificing control.

• Cost Control: Less bead loss and fewer reworks protect margins as volumes rise.

• Scalability: Parameters scale from small runs to tens of liters with predictable outcomes.

- A Note On Data That Matters

While every process is different, we focus on a few numbers that move the needle: batch volume in liters, immobilization time per step, and bead recovery rate. By tuning the Magnetic Separation System to maintain a uniform field and by observing real-time separation signals, customers routinely shorten step times while improving recovery – two metrics that define sustainable scale-up.

Ready To Fix Multi-Liter Bottlenecks?

If your Magnetic Separation System slows down or sheds yield at scale, Longlight Technology can help you stabilize field uniformity, cut bead loss, and simplify your workflow. Request a process review and on-site demo to see how our approach turns multi-liter batch processing into a reliable, safe, and economical operation.

Call-to-Action: Contact Longlight Technology to discuss your application and schedule a pilot run – let’s say goodbye to scale-up surprises and build a clean path from R&D to production.