Related Post

Frequent Extraction Failures Solved by Magnetic Separator For Nucleic Acid Purification

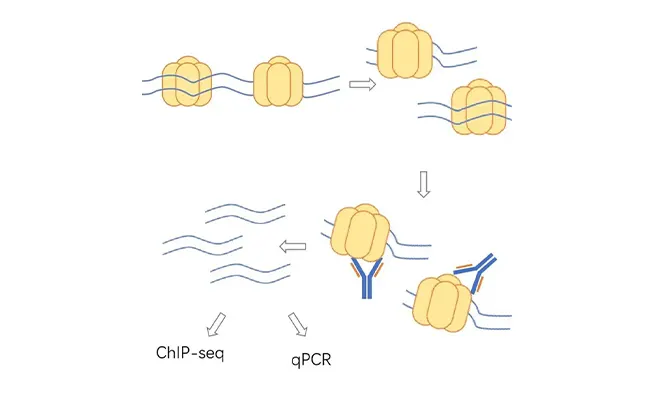

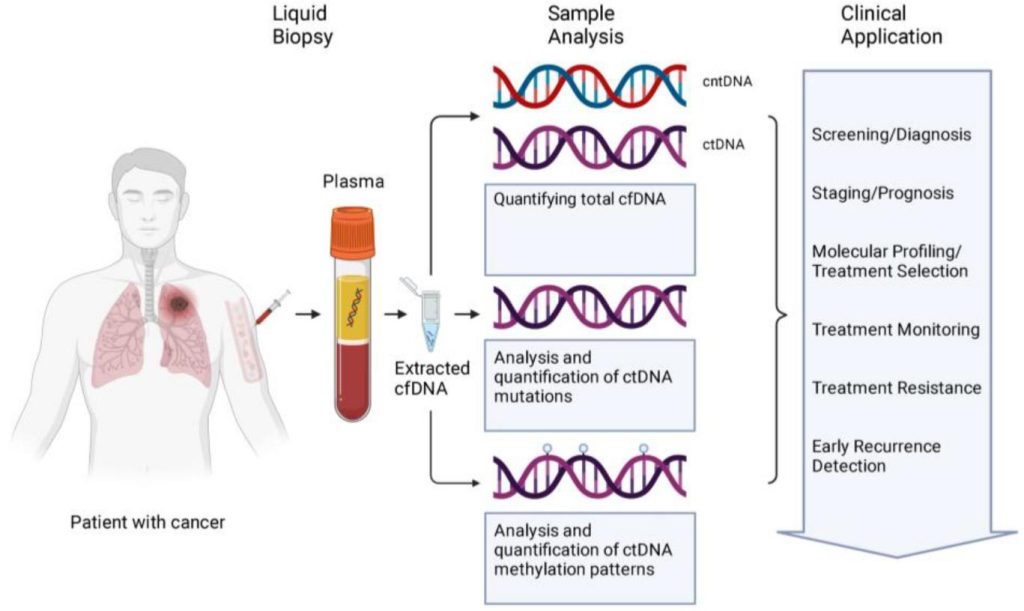

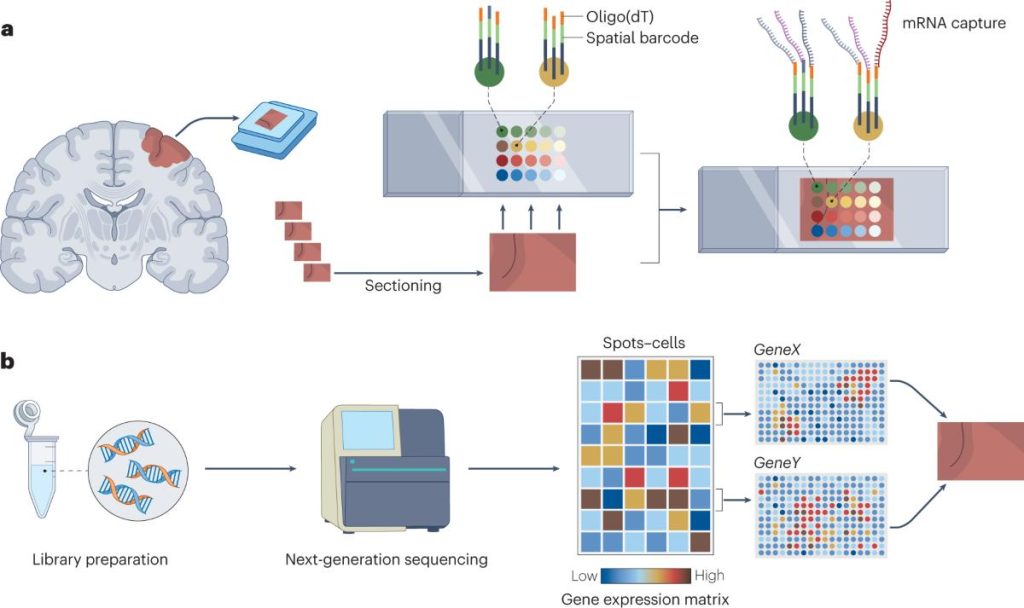

2025-09-25Magnetic Separator For Nucleic Acid Purification now underpins global work in nucleic acid separation, protein cleanup, cell sorting, biocatalysis, diagnostic assay manufacturing, single-cell proteomics, synthetic biology, and reagent development. Internationally, magnetic bead-based purification has powered landmark efforts in population-scale genomics and pathogen surveillance, enabling millions of DNA/RNA preparations during COVID-19 testing and ongoing global sequencing initiatives. Using a Magnetic Separator For Nucleic Acid Purification, labs gain fast, reproducible cleanup for high-throughput library prep, qPCR, and automation-ready workflows. Applications span NGS library cleanup; viral RNA extraction; cfDNA/ctDNA liquid biopsy; microbiome and metagenomic studies; single-cell and spatial transcriptomics prep; CRISPR-based diagnostics; environmental and wastewater monitoring; food-safety and agricultural testing; bioprocess monitoring and QC; and routine clinical and academic core facilities – where consistency, scale, and operator safety are essential.

(Using cfDNA and ctDNA as Oncologic Markers: A Path to Clinical Validation)

From the floor of our own production area at Longlight Technology, we hear the same goals from teams across these programs: push yield up, drive contamination down, keep results consistent, and do it safely at a scale that makes sense for real throughput. The hard part is delivering several-liter batches while protecting valuable magnetic beads and preserving a validated process that must perform every single day.

Where Mistakes Creep In – And How a Magnetic Solution Breaks the Cycle

Many labs still rely on centrifuges and repeated manual transfers. Those steps create opportunities for error: shear forces can damage material, handoffs add variability, and large permanent magnets can introduce safety concerns. Problems grow as methods move from benchtop milliliters to production-level volumes. Our answer at Longlight Technology is simple in idea and careful in execution: design a Magnetic Separator For Nucleic Acid Purification that removes weak links, standardizes physics across the entire working zone, and scales without rewriting the playbook.

We engineer a uniform, stable magnetic field that blankets the full separation area so each bead experiences the same force. That design prevents local hot spots and bead stacks, which are common triggers for incomplete washing and carryover. With a consistent field, capture behavior stays predictable when you change tube size, bag geometry, or batch volume. The same principle helps with operator safety. A dedicated protective structure and controlled access to the magnetic core reduce risk compared with traditional large magnets, improving daily ergonomics without compromising performance.

• Uniform Field, Predictable Behavior

When a field is uneven, beads collect in dense ridges. Wash buffers then bypass these piles, leaving impurities behind. By keeping the field even, we avoid aggregation, shorten immobilization when needed, and allow clean resuspension. Fewer wash cycles and smoother bead motion translate into less sample loss and tighter purity specs. It’s a small design decision that changes day-to-day results.

The Errors We See Most – And How We Remove Them

Across discovery, pilot, and manufacturing, the same patterns repeat. What differs is the cost of failure: in production, a small error becomes scrap; in R&D, it burns limited sample and time. Our platform targets the root causes with real-time visibility and bead-friendly motion so your method stays intact as your volume grows.

- Bead clumping and poor washes: A uniform field geometry prevents bead piles, so washes reach every surface and elutions run cleaner.

- Under-capture or over-capture: Step-specific timing by volume and viscosity keeps immobilization in the sweet spot, improving yield and purity.

- Carryover between steps: Guided workflows limit open handling and touchpoints, cutting the routes by which contamination spreads.

- Losses during spins and transfers: One-step magnetic holds replace many centrifuge cycles, protecting fragile nucleic acids and saving hands-on time.

- Run-to-run variability: Consistent field strength and automated timing narrow your process window and support QC release.

- Slow turnaround: Streamlined magnetic protocols reduce total cycle time and make training straightforward for new operators.

In settings where instruments run all day, speed and repeatability matter more than any single metric. That is why we include continuous monitoring of separation events. If a hold step starts drifting – say due to viscosity change or temperature – the system flags it before the batch falls out of spec. The same controls help high-throughput DNA programs, where high-throughput DNA magnetic bead purification places a premium on gentle handling and clean separations for downstream sequencing and qPCR.

✅ Monitoring and Control That Guards Your Outcome

Think of monitoring as a seatbelt for your SOP. Sensors and logged parameters confirm that each immobilize-wash-elute sequence hit the intended timing and threshold. If the process needs an adjustment – longer immobilization, slower decant, a repeat wash – you act in time. That record also simplifies audits and accelerates investigations when results look unusual. The value compounds when you scale, because consistent control means fewer surprises as batch size grows.

(Single-cell and spatial transcriptomics: deciphering brain complexity in health and disease | Nature Reviews Neurology)

From Pilot to Plant – Longlight Technology‘s Way of Scaling

We build for scientists who write SOPs and for manufacturing teams who must deliver against plan. Our Magnetic Separator For Nucleic Acid Purification supports batch operation for large-scale biomagnetic separation and is equally comfortable in nucleic acid purification, protein cleanup, cell applications, biocatalysis, and diagnostics. A modular design lets you start small, then expand capacity without rethinking the workflow. Real-time monitoring provides visibility at each stage. Safety features protect staff from the hazards common to traditional large magnets. The interface favors clarity, and training is measured in hours, not weeks.

Longlight’s approach is deliberately practical. We conserve raw materials by minimizing bead loss. We keep the physics the same when you change container size. We design motion and timing to respect the paramagnetic behavior of your beads and the viscosity of your buffers. And we give you control without unnecessary complexity, so the process remains teachable and auditable.

✅ What you gain in practice

- Consistency you can defend: Stable fields and logged parameters support validation and ongoing quality assurance.

- Better capture with fewer steps: Optimized windows for immobilization and wash reduce waste and improve output.

- No-spin simplicity: Magnetic holds stand in for many centrifuge runs, cutting cycle time and hands-on fatigue.

- True scale-up: Milliliter trials translate to several-liter batches with custom volume options, not just parallelization.

- Operator confidence: Protective design reduces risk while preserving access for observation and maintenance.

For teams planning growth, an automated magnetic bead extraction system is one of the few upgrades that lowers risk as it raises throughput. It compresses hands-on time, reduces training burden, and improves documentation. It also trims reagent use by avoiding over-washing and preventing bead loss. Those gains matter when you produce critical kits, support clinical pipelines, or run multiple lines around the clock.

A Partner in the Work, Not Just a Piece of Hardware

At Longlight Technology, we do not ask you to rewrite your chemistry to fit our device. Instead, we map your protocol, identify friction points, and tune separation timing and field exposure to your specific beads and buffers. That is how a Magnetic Separator For Nucleic Acid Purification becomes a stable part of your method rather than a variable you must manage. When you move from pilot to routine production, the same physics stay with you – only the volume changes.

Call to Action: If you are fighting low yield, contamination risk, or scale-up headaches, let’s talk. Contact Longlight Technology for a technical consultation or on-site demo. We will review your current workflow, share concrete adjustments, and show how a Magnetic Separator For Nucleic Acid Purification can turn a fragile step into a reliable advantage.