Related Post

How Probe-free Ultrasonicator Stops Cross-Contamination Risks

2025-09-26Probe-free Ultrasonicator technology is changing how modern labs eliminate cross-contamination while keeping everyday workflows fast, clean, and consistent. Well-known international research on the Probe-free Ultrasonicator highlights how non-contact, confocal acoustics lower cross-contamination and improve run-to-run reproducibility in multi-site workflows. By focusing high-frequency energy through an acoustic medium, laboratories achieve tightly controlled shearing without a metal probe, reducing operator variability and protecting heat-sensitive samples. Reported outcomes include more consistent fragment profiles, fewer reruns, and cleaner baselines across genomics pipelines.

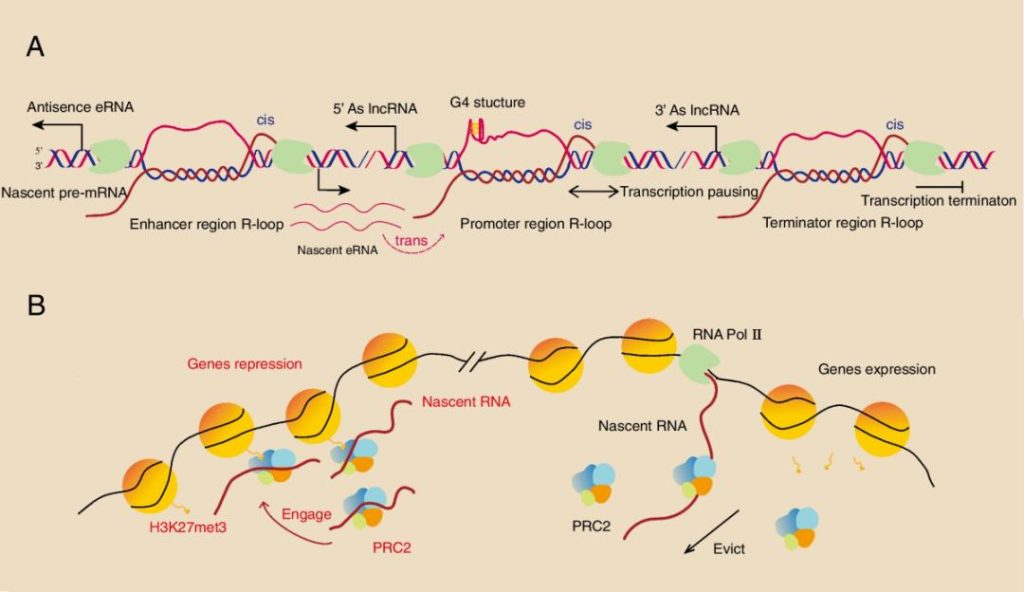

(The chromatin-associated RNAs in gene regulation and cancer | Molecular Cancer )

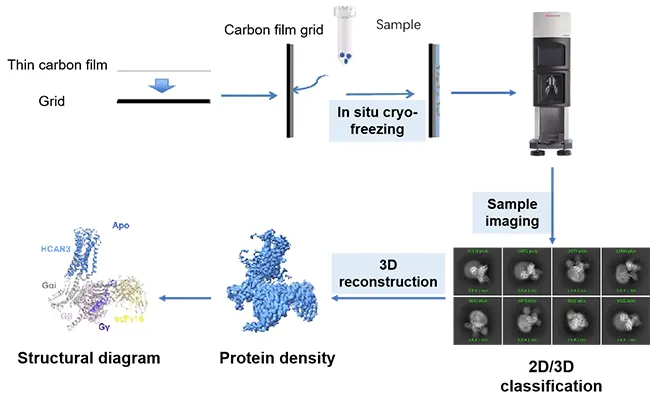

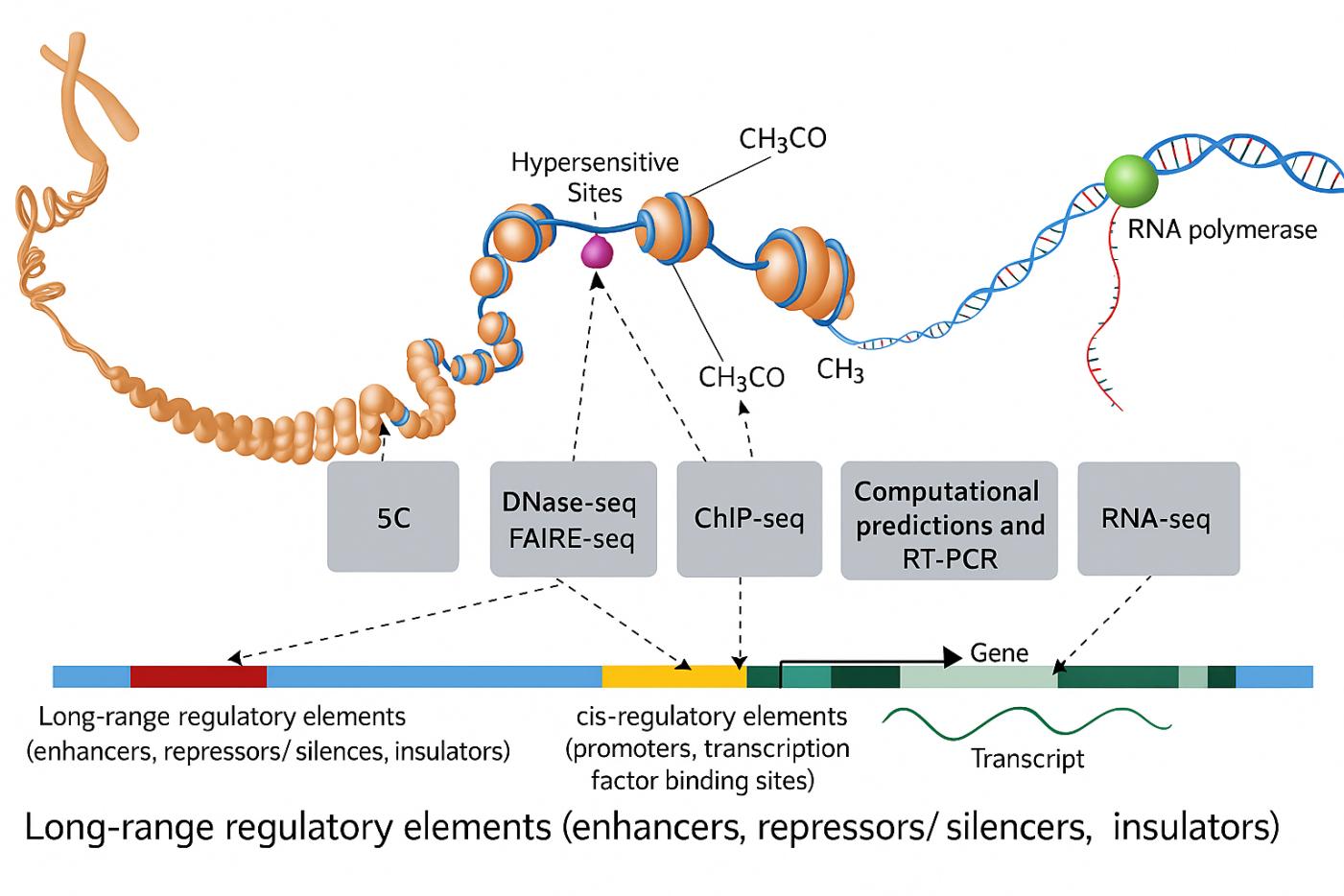

Applications of a Probe-free Ultrasonicator include DNA/RNA/chromatin shearing, genome fragmentation for NGS, FFPE deparaffinization, cell and tissue disruption for protein or nucleic acid extraction, tissue homogenization, and ChIP-seq workflows. These use cases benefit from standardized energy delivery, precise temperature control, and minimal cleaning between runs.

How a Probe-free Ultrasonicator Ends Carryover at the Source

At Longlight Technology, we design non-contact acoustic systems to remove the usual culprits behind contaminated data: metal probes, heavy manual handling, and temperature drift. Traditional sonication brings a probe into the vial. Even with careful cleaning, the surface can harbor residues, wear down, or shed particles over time. The result is familiar – unwanted carryover, questionable datasets, and expensive reruns.

Our Probe-free Ultrasonicator sends focused, high-frequency, short-wavelength energy through an acoustic medium. The sample never touches a probe. Energy is concentrated precisely where it’s needed by confocal acoustics, giving you tight control of shearing or disruption parameters without a mechanical interface. In practice, that means fewer variables to chase and more confidence that today’s run will match last week’s run.

We build from a simple principle: if you can standardize energy delivery and keep the sample isolated, you minimize cross-contamination risk and improve reproducibility. The approach supports consistent fragment profiles and cleaner extractions across users, shifts, and instruments – key gains for regulated or high-throughput labs.

✅ Pain Points We Eliminate

- Carryover from metal surfaces: No direct probe contact, no post-run residue to manage.

- Manual variability: Click-to-run setup limits operator-dependent steps and reduces training burden.

- Probe wear and maintenance: No consumable tips or polishing cycles to schedule between runs.

- Aerosol and splash concerns: A closed, non-contact path reduces exposure risks for sensitive assays.

- Thermal drift: Active sensing and feedback control keep the sample in a stable temperature window.

Designed for Real Labs: Control, Cooling, and Quiet Operation

Precision starts with temperature. Heat spikes during sonication can distort fragment size or degrade sensitive targets. Our system uses high-sensitivity sensing and closed-loop control to maintain true low-temperature, constant-temperature processing in the active sample zone. You set the range; the controller holds it steady, even through aggressive cycles.

Cooling is built in. A high-efficiency semiconductor refrigeration module rapidly pulls down the sample area and shortens time between runs. There’s no external chiller to plumb, monitor, or service. The all-in-one design keeps the footprint compact and the bench uncluttered, which matters when every square centimeter is spoken for.

Noise is another practical barrier in many labs. Because our Probe-free Ultrasonicator operates quietly without a sound-insulating hood, you can place it where the work happens – next to liquid handling, library prep, or extraction – without disrupting the room. Quiet hardware is more than a comfort feature; it’s an enabler of lean layouts and faster handoffs.

Finally, we obsess over usability. Load the sample, choose or enter a small set of parameters, and press run. The interface favors clarity over complexity. By keeping the number of decisions small and visible, we reduce setup errors and accelerate onboarding for new staff.

✅ What You‘ll Notice in Week One

- Cleaner baselines: Fewer suspicious reads and fewer outliers after switching off probes.

- Shorter turnaround: Rapid cool-down and minimal cleaning steps keep the queue moving.

- Consistent outcomes: Confocal focusing delivers similar energy profiles across runs and users.

- Less bench chaos: No external PC or chiller, fewer cables, smaller footprint.

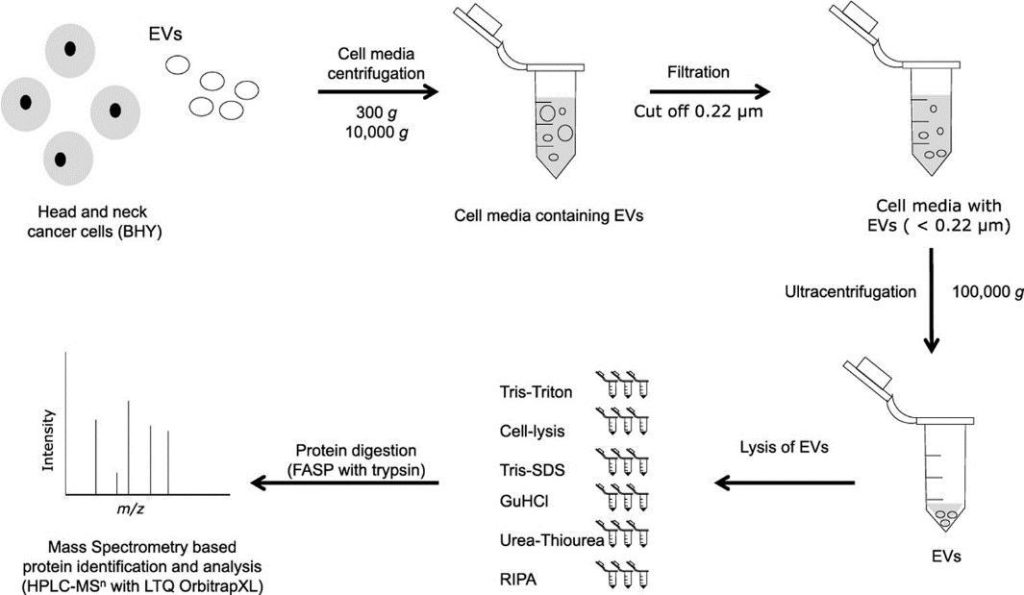

(Comprehensive Guide to Cell Lysis and Protein Extraction Method – Creative Proteomics)

From Research to Routine: Applications and Adoption

Cross-contamination prevention is not only about avoiding disastrous carryover events; it’s about protecting daily decisions. If the sample is rare, precious, or costly to acquire, non-contact processing is the safer path. Our Probe-free Ultrasonicator supports core genomics tasks where cleanliness and control pay off immediately.

In DNA, RNA, and chromatin shearing, precise energy delivery shapes fragment distributions and reduces rework. In genome fragmentation for NGS, standardized energy and temperature improve library quality and reduce the number of samples that need to be repeated. FFPE deparaffinization benefits from uniform energy input without hot spots, while cell and tissue disruption gains from stable temperature and minimized aerosol formation. For ChIP-seq and other chromatin assays, consistent shearing protects the interpretability of peak calls and reduces variability between batches.

Longlight Technology offers more than a single instrument. We support end-to-end workflows with genomics tools and selected consumables – such as precast agarose gels, nucleic acid scavengers, Qubit tubes, nucleic acid extraction kits, and library preparation kits – so you can streamline sourcing and validation. This ecosystem is designed to shorten the path from evaluation to routine use.

Implementation is straightforward. Most labs begin with a small pilot focused on one pain point – often cross-contamination prevention in NGS workflows or a troublesome extraction step – then extend the configuration once the baseline metrics improve. Because the system is integrated and quiet, you rarely need to rearrange benches or add infrastructure. Our team assists with initial parameter templates and helps you translate your legacy probe-based settings into a non-contact profile. The outcome is a documented method that operators can run confidently and auditors can follow.

We also recognize that every lab has its own rhythm. Some prioritize maximum throughput; others value gentle processing for sensitive material. Confocal acoustics make those trade-offs explicit. You can tune energy density, cycle time, and temperature limits, and count on the controller to deliver what you set. The shift from “best effort” to non-contact ultrasonic sample processing with feedback control is often what finally stabilizes month-to-month performance.

As a manufacturer, our role is to bring practical engineering to scientific goals. That means reducing moving parts, hiding complexity behind clear interfaces, and eliminating maintenance tasks that don’t add scientific value. It also means designing for the realities of shared spaces, rotating staff, and changing throughput targets. A Probe-free Ultrasonicator meets those realities by isolating the sample from hardware, standardizing energy delivery, and keeping temperature steady – three levers that, together, remove most routes to cross-contamination.

Ready to See It in Your Workflow?

If carryover, inconsistent shearing, or temperature-related artifacts are undermining your results, it’s time to simplify. Request a demo or workflow review with Longlight Technology. We’ll map your current protocol, identify contamination touchpoints, and propose a focused, confocal acoustic setup that protects your samples and your credibility. With a Probe-free Ultrasonicator at the core of your process, you can move faster, repeat less, and trust the data you publish.