Related Post

Common Mistakes When Selecting a Vacuum Centrifuge Concentrator

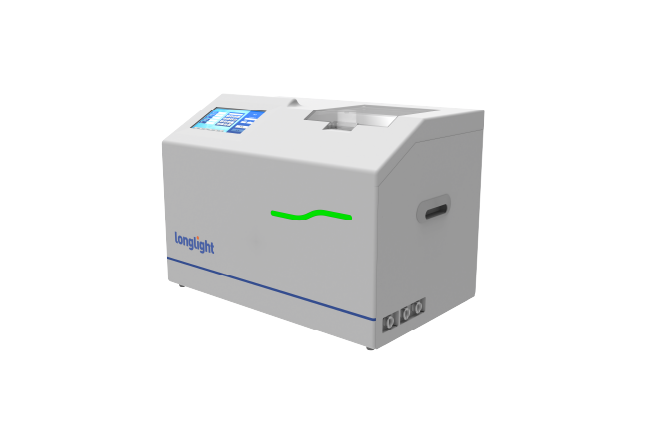

2025-08-21Selecting A Vacuum Centrifuge Concentrator can be a surprisingly risky decision for any busy laboratory – one mis-step and precious samples, budgets, and timelines all suffer. At Longlight Technology, we see the hidden pain points every day, and in this article we share what goes wrong, why it hurts, and how our LLV-1 Vacuum Centrifugal Concentrator prevents costly detours.

Why Labs Get It Wrong when Selecting A Vacuum Centrifuge Concentrator

Even experienced scientists stumble when selecting a vacuum centrifuge concentrator for DNA/RNA, oligonucleotides or fragile proteins. The brochures promise “gentle evaporation,” yet many units deliver uneven heat bursts that quietly damage samples. You won’t notice the harm until QC spikes, sequencing reads collapse, and precious reagents need replacing – a costly hit for lean R&D teams working against tight release dates.

Heat load is only the first trap. Pressure swings, rotor mismatch and adapter fatigue add new avenues for error:

- Uneven heating – thin-wall tubes scorch first, skewing concentration curves and wasting reagents.

- Vacuum instability – pressure rebounds splash condensate, cross-contaminating lanes and losing supernatant.

- Rotor mismatch – adapters that don’t hug tube geometry develop micro-cracks that leak vapor and aerosols.

• Overlooking Total Cost of Ownership

Initial price tags can be seductive, but the real expense surfaces months later when solvents etch an un-coated chamber or a low-grade pump head corrodes. Every unplanned shutdown stalls sequencing queues, delays clinical milestones and burns credibility with stakeholders.

•Maintenance gaps – non-Teflon pumps seize after a month of acetonitrile exposure.

•Energy drain – outdated drives draw excess current, triggering facility power audits.

•Disposable creep – work-around rotors need custom gaskets that quietly inflate consumable budgets.

Ask any lab manager: overnight shipping a replacement seal costs less than the idle day it “saves.” The lesson is clear – buy cheap, pay twice, delay indefinitely.

How Longlight Technology‘s LLV-1 Ends the Trial-and-Error Cycle

Longlight engineers built the LLV-1 after watching customers fight these exact problems. Our design brief was simple: protect heat-sensitive molecules, resist aggressive solvents, and get busy scientists from sample to data without drama.

•Smart Design for Sensitive Workflows

At the core is a two-stage temperature system. One sensor stabilizes the rotor jacket at a mild set-point; a second tracks lid atmosphere, smoothing gradients that stress biomolecules. A stainless-steel cavity coated inside and out with Teflon laughs at acetonitrile, methanol, and formamide. A pure-PTFE diaphragm pump pulls a deep, steady vacuum – no oil, no back-stream, no smell.

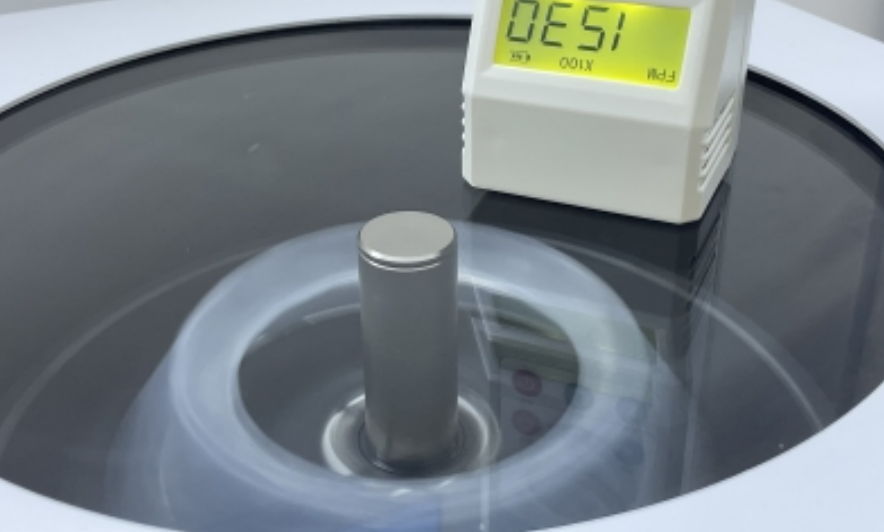

The electromagnetic drive suspends 90 x 1.5 mL tubes in perfect balance, eliminating the vibration that cracks pellet rims. Your DNA pellets remain intact, proteins stay folded, and yield curves stay linear from first run to thousandth.

•Operational Simplicity That Boosts Uptime

An instrument that needs a thick manual is already broken. LLV-1 offers four one-touch shortcuts plus thirty user programs; technicians can flip from qPCR prep to metabolomics without re-entering parameters. The digital anti-corrosion vacuum gauge shows real-time mBar values, so operators instantly see if viscous lysates are still outgassing or if the run is ready to finish. When the cycle ends, an imported pressure-relief valve vents automatically – no more wrestling knobs or blasting ambient air onto fragile pellets.

- Programmable safety – two-stage control halts overheating before it starts.

- Low vibration – electromagnetic suspension keeps pellets intact, improving recovery yields.

- Rich accessories – interchangeable rotors and cold traps support micro-strips to conicals, perfect for fast-changing NGS workflows.

•The Longlight Commitment

We know that selecting a vacuum centrifuge concentrator is more than a line item; it is a direct investment in the integrity of your data. That is why every LLV-1 ships with lifetime technical support, a solvent-proof warranty, and upgrade-ready firmware that grows with new protocols.

Your Next Step: Selecting A Vacuum Centrifuge Concentrator with Confidence

Ready to Talk to Our Engineers?

Longlight Technology has spent years listening to front-line scientists, and the LLV-1 is our answer to their top frustrations in Selecting A Vacuum Centrifuge Concentrator. If you’re tired of rerunning assays, writing deviation reports, or watching corrosion eat away capital equipment, let’s fix it together. Visit our product page, book a virtual demo, or email marketing@longlightech.com for a tailored ROI analysis.

Act now: every sequencing day saved is a week shaved off your development timeline. Click below, and make sample loss a thing of the past.

Longlight Technology – Concentrate on Discovery, not Equipment.