Related Post

Ultrasonic Homogenizer vs Conventional Mixing Techniques

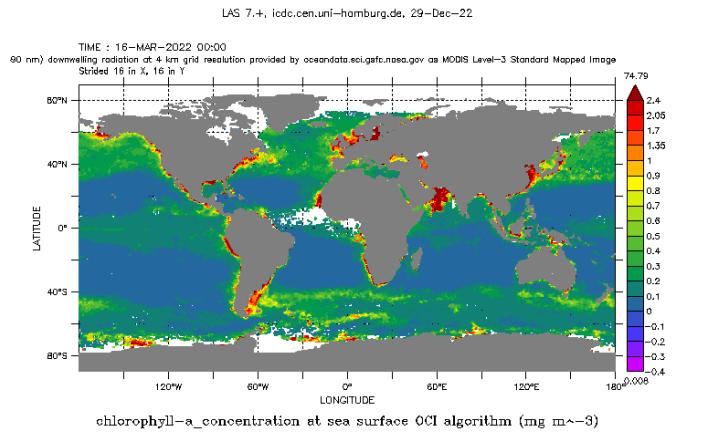

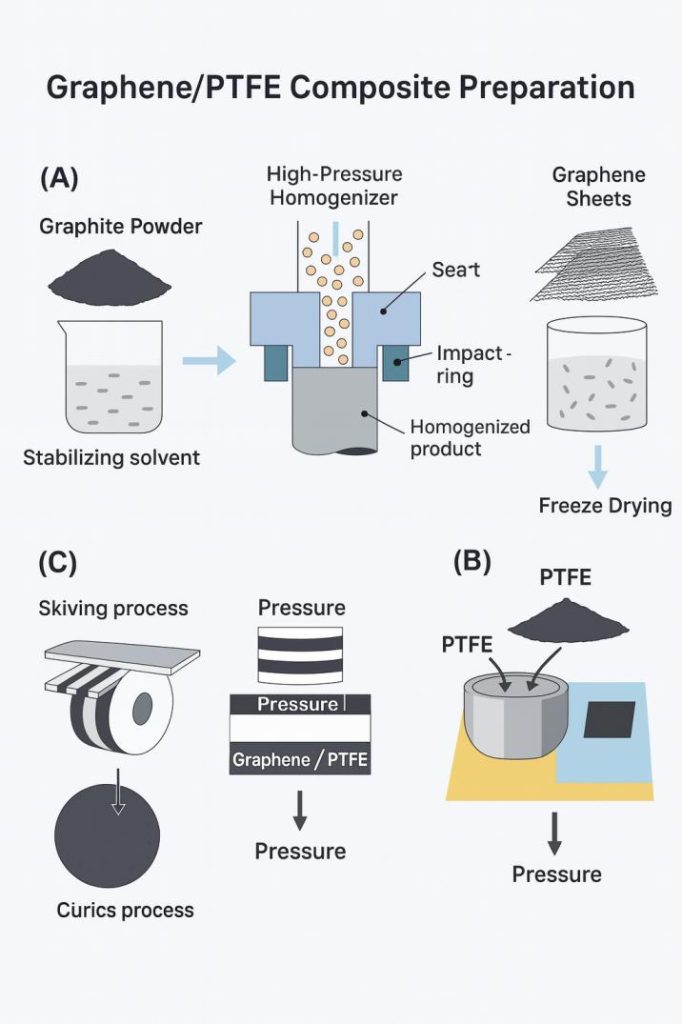

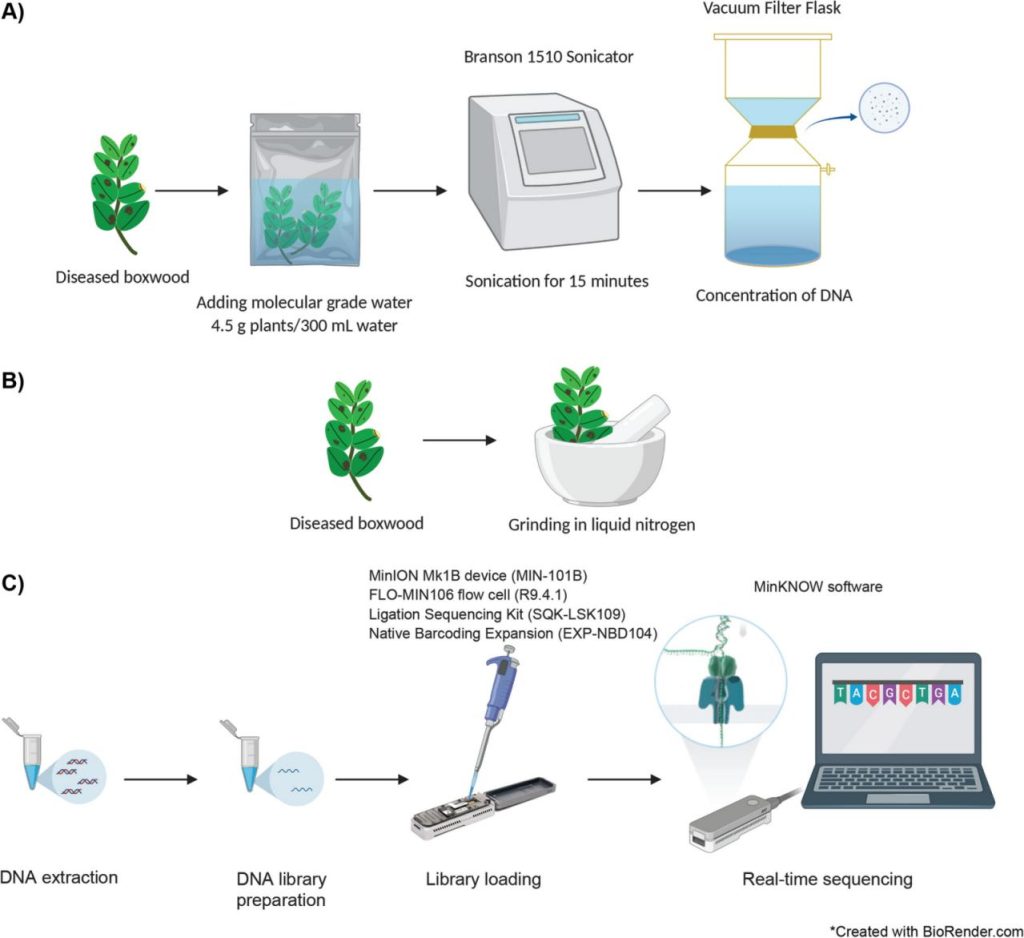

2025-09-23An ultrasonic homogenizer is reshaping how labs prepare samples, protect integrity, and standardize workflows. Ultrasonic homogenizers have powered influential international research across nanomaterials and life sciences. Liquid-phase exfoliation studies popularized by Coleman and colleagues used ultrasonication to produce stable graphene and 2D-material dispersions, accelerating worldwide work in printable electronics and catalysis. In biology, large metagenomics and plant-transcriptomics efforts adopted sonication-based lysis to standardize sample prep and boost nucleic-acid yields. Key application areas: rapid cell/tissue disruption; DNA/RNA/protein extraction; chromatin shearing; nanoparticle and pigment dispersion; nanoemulsion and liposome sizing; drug-delivery and vaccine-formulation screening; food and cosmetic emulsification; environmental microbiology; polymer chemistry; degassing and cleaning of labware. Precise control of amplitude, pulse duty, and temperature ensures reproducibility while protecting heat-sensitive targets. At Longlight Technology, we work with teams that balance speed against control, throughput against reproducibility, and efficiency against sample safety. This article explains where ultrasonic energy outperforms conventional mixers, how our focused ultrasonication approach reduces variability, and when a classic method still makes sense.

(Liquid-Phase Exfoliated Graphene and Polytetrafluoroethylene for Highly Durable

and Reusable Chemical Leak Detection Sensors)

Rethinking Mixing: Where Ultrasound Wins – and Where It Doesn‘t

Traditional mixing – vortexing, bead beating, blade stirring – depends on contact, hardware wear, and operator technique. Outcomes shift with tool age, batch size, and handling. Heat hot-spots appear without warning. Cross-contamination risks rise when probes or beads meet precious material. These are the hidden costs: rework, repeat runs, and slower decisions.

An ultrasonic homogenizer approaches the problem differently. High-frequency, short-wavelength sound concentrates energy into the sample. In our focused system, the acoustic field couples through a medium, so there is no direct tool-to-sample contact. Fewer variables enter the equation. Fragile biomolecules encounter less mechanical stress. And because temperature is sensed and controlled at the sample zone, heat is managed before it can skew downstream analysis.

For NGS, molecular diagnostics, proteomics, and high-value discovery projects, repeatability is the real currency. Focused ultrasonication delivers targeted energy with automated control. That reduces operator-introduced error and tightens your coefficients of variation. If you are comparing options for an ultrasonic homogenizer for DNA shearing, the ability to hold a low, constant temperature during sonication is a practical advantage, not a minor detail.

• Where Traditional Mixing Still Fits

Not every task needs ultrasound. Classic mixers excel at simple buffer preparation, bulk blending of non-sensitive fluids, and quick pre-dissolution steps. If contact is acceptable and slight heating poses no risk, a standard mixer remains efficient. But when you must standardize across many samples – or when contamination and heat truly matter – focused ultrasonication is the smarter default.

Inside Longlight‘s Focused Ultrasonication Platform

From the manufacturer’s perspective, control and consistency start with acoustics. Our approach uses advanced confocal acoustics to focus energy exactly where it is needed. The result is a highly controllable process that improves repeatability and efficiency and supports standardized results across runs and operators. Quiet operation means you can place the instrument almost anywhere on the bench; no extra sound enclosure is required. An integrated footprint removes the need for an external computer or chiller, which simplifies setup and frees space.

At the user level, setup is minimal. Place the sample, enter a few parameters, and press run. The system takes care of energy delivery, thermal stability, and runtime consistency. The goal is not just speed – it is speed with confidence.

✅ Capabilities That Tackle Real Lab Pain Points

- Non-contact processing: Focused ultrasonic energy acts through an acoustic medium, reducing contamination risk compared with probe-based systems.

- True low and constant temperature: High-sensitivity sensing and control keep the sample within range, helping protect results from sonication-induced heat.

- Quiet, bench-friendly operation: Use it in standard lab space without additional insulation.

- Simple, guided workflow: Fewer steps mean easier training and less operator variation.

- Fast, integrated cooling: A high-efficiency semiconductor refrigeration system accelerates cool-down to stabilize conditions.

- All-in-one design: No external refrigeration or PC, which saves bench space and reduces points of failure.

(Metagenomic sequencing for detection and identification of

the boxwood blight pathogen Calonectria pseudonaviculata | Scientific Reports)

✅ Applications That Benefit from Focused Ultrasonication

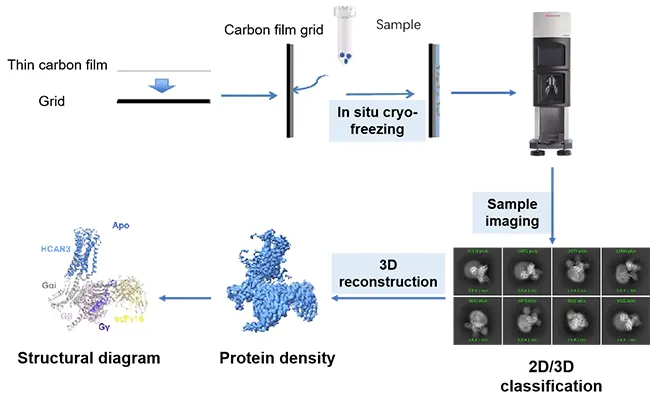

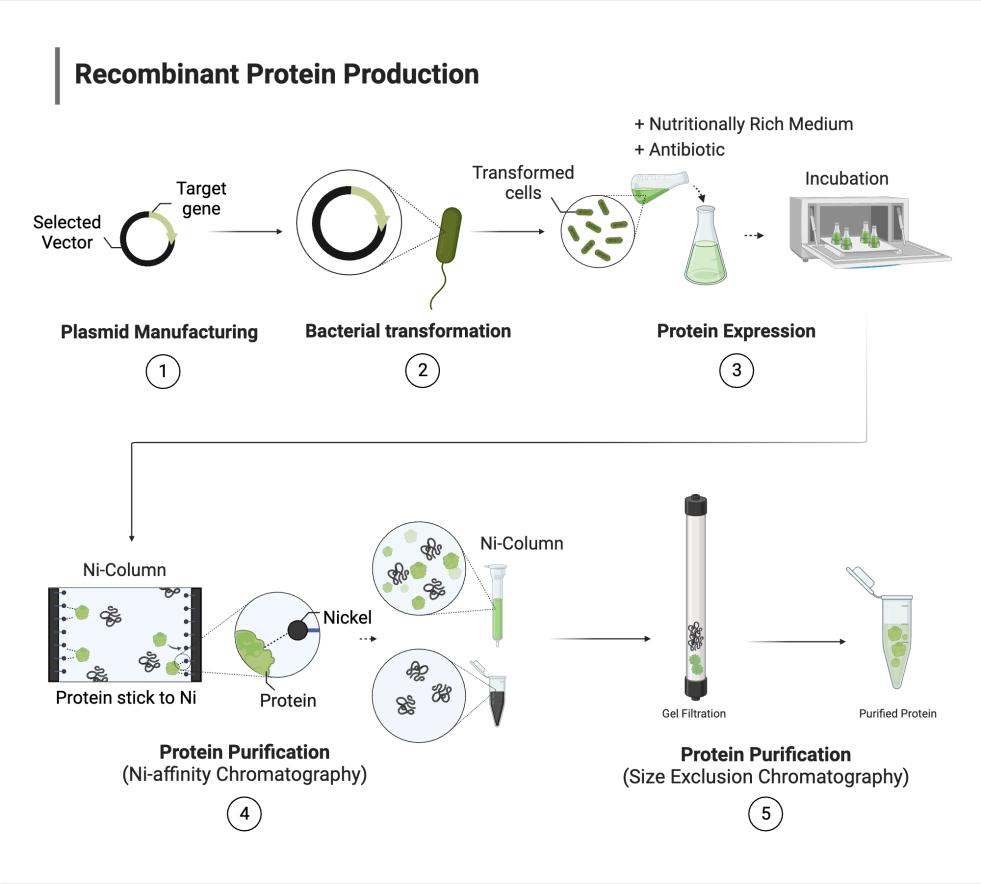

- DNA, RNA, and chromatin shearing

- FFPE deparaffinization

- Genome fragmentation for NGS

- Cell and tissue disruption for genome or protein extraction

- Fragmentation and homogenization of biological tissues

- ChIP and ChIP-seq workflows exploring protein-chromatin interactions

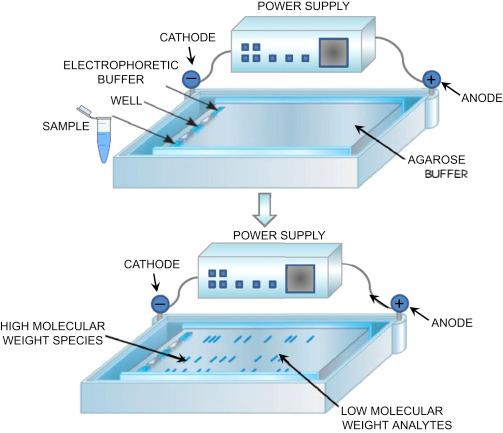

Our portfolio supports these pipelines from start to finish. Beyond instruments, Longlight provides precast agarose gels, nucleic acid scavengers, Qubit tubes, nucleic acid extraction kits, and library preparation kits. These tools are used across academic, clinical, and industrial labs. Pairing them with focused ultrasonication sample prep reduces variability and makes multi-site protocols easier to standardize.

Making the Right Choice: Practical Criteria and Next Steps

Selecting between an ultrasonic homogenizer and a traditional mixer is not only a budget call – it is a data-quality decision. Use this quick guide to align method with outcome:

• Choose traditional mixing when preparing simple buffers, blending non-sensitive liquids, or performing steps where contact and mild heating are acceptable.

• Choose focused ultrasonication when reproducibility, contamination control, and thermal stability drive your results – or when consistency across batches and operators is critical.

Consider three questions as you decide:

❓ How sensitive is your target? If nucleic acids or proteins can be damaged by heat or shear, precise acoustic control is protective.

❓ How many samples must match? Standardized energy delivery and non-contact processing help align results across plates, runs, and sites.

❓ What is the true cost of repeat runs? Avoiding rework often saves more time and budget than a lower upfront equipment cost.

At Longlight Technology, our mission is to make designed sample preparation the new normal. By focusing acoustic energy where it matters and stabilizing temperature in real time, we help labs move past trial-and-error and toward reliable, decision-ready data. Whether your team runs high-throughput NGS or targeted assays, the right tool should accelerate your science – without adding complexity.

Call to Action: If you are ready to move from variable mixing to focused, reproducible ultrasonication, connect with Longlight Technology. Request a quick workflow assessment, schedule a live demonstration, or ask for guidance on reagents and kits that complement your protocols. Let’s build a faster, cleaner, and more consistent pipeline – starting with the ultrasonic homogenizer that fits your lab.