Related Post

Complex Samples? One-Stop Ultrasonicator for DNA Extraction

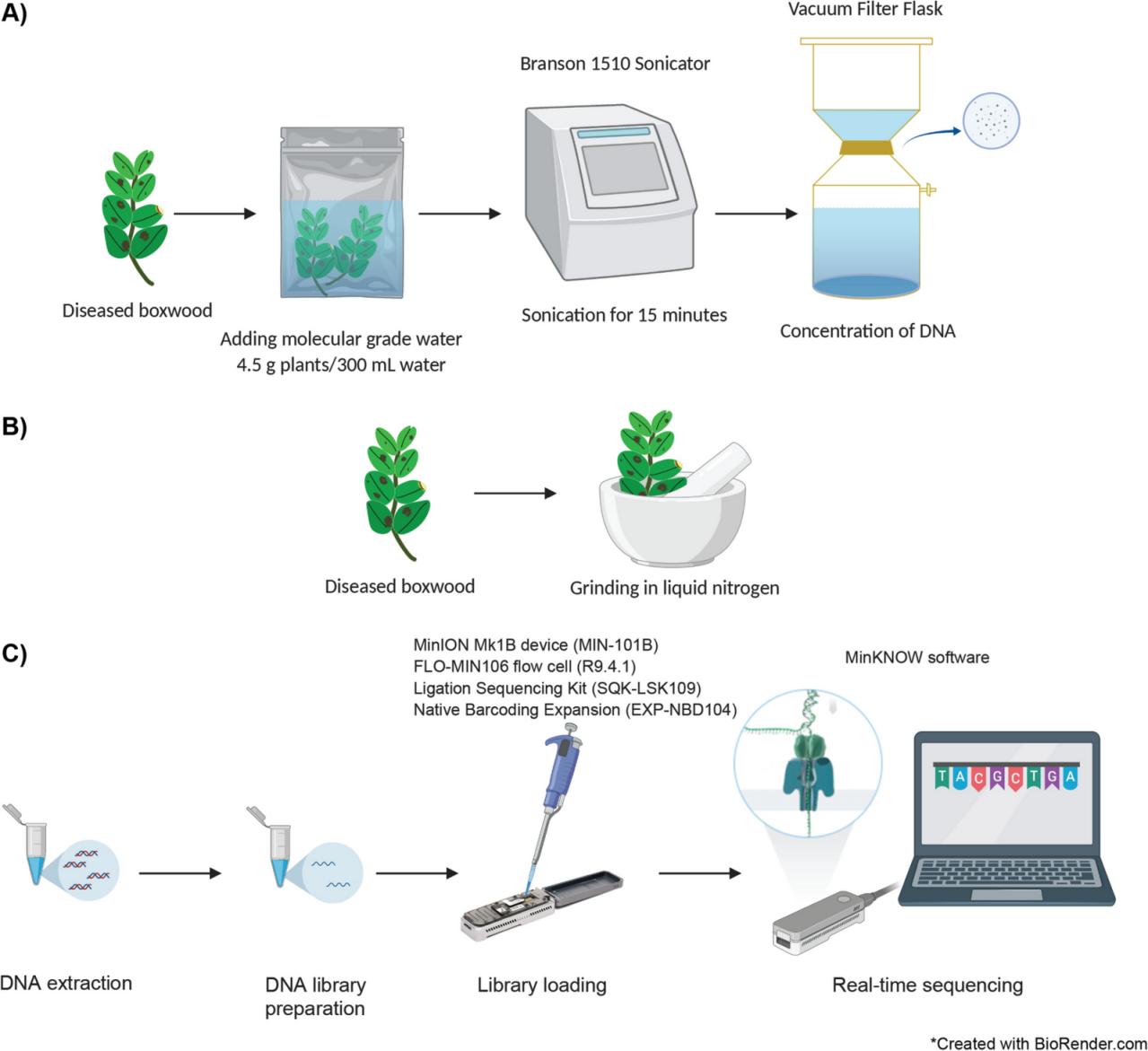

2026-01-12A Ultrasonicator for DNA Extraction concentrates high-frequency acoustic energy into a sealed microenvironment. It lyses cells and releases nucleic acids in a sealed, noncontact environment, while tightly controlling temperature to preserve DNA integrity. When required, controlled acoustic exposure can also be applied for downstream fragmentation. It supports heterogeneous, viscous, or low-biomass matrices. What enables such control and reproducibility, and how can it standardize your workflow? The details and evidence follow.

What Is an Ultrasonicator for DNA Extraction?

An Ultrasonicator for DNA Extraction is a focused acoustic system that concentrates high-frequency, short-wavelength sound into a tightly defined sample zone. Rather than immersing a metal probe or relying on a generic bath, the instrument delivers energy through an acoustic medium without touching the sample. By eliminating direct contact, it reduces contamination risk, avoids aerosol generation, and curbs heat-driven artifacts that can skew fragment profiles.

At Longlight Technology, we employ focused acoustic geometry to maintain a stable, near-isothermal environment during processing. Samples remain sealed in closed tubes, while precisely metered ultrasonic energy fragments DNA or disrupts cells and tissues. This closed-tube, noncontact approach consistently produces narrow fragment-size distributions and stable recovery across runs. It shines with challenging matrices – biofilms, viscous clinical samples, formalin-treated tissues – where legacy probe or water-bath sonication often varies widely. In short, a modern Ultrasonicator for DNA Extraction integrates gentle, precision-controlled acoustics with strong consistency, enabling downstream success in genomics and proteomics workflows.

Global Research and Proven Use Cases

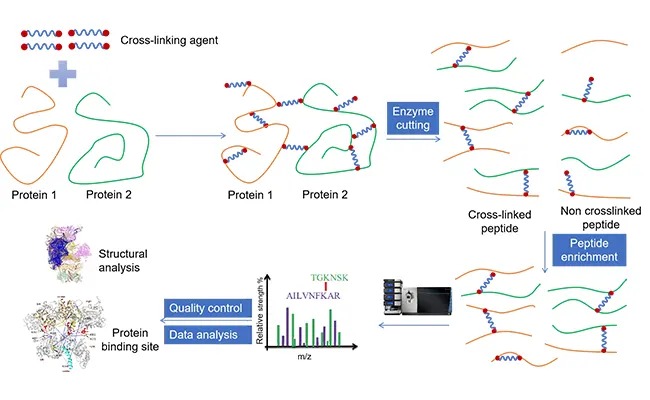

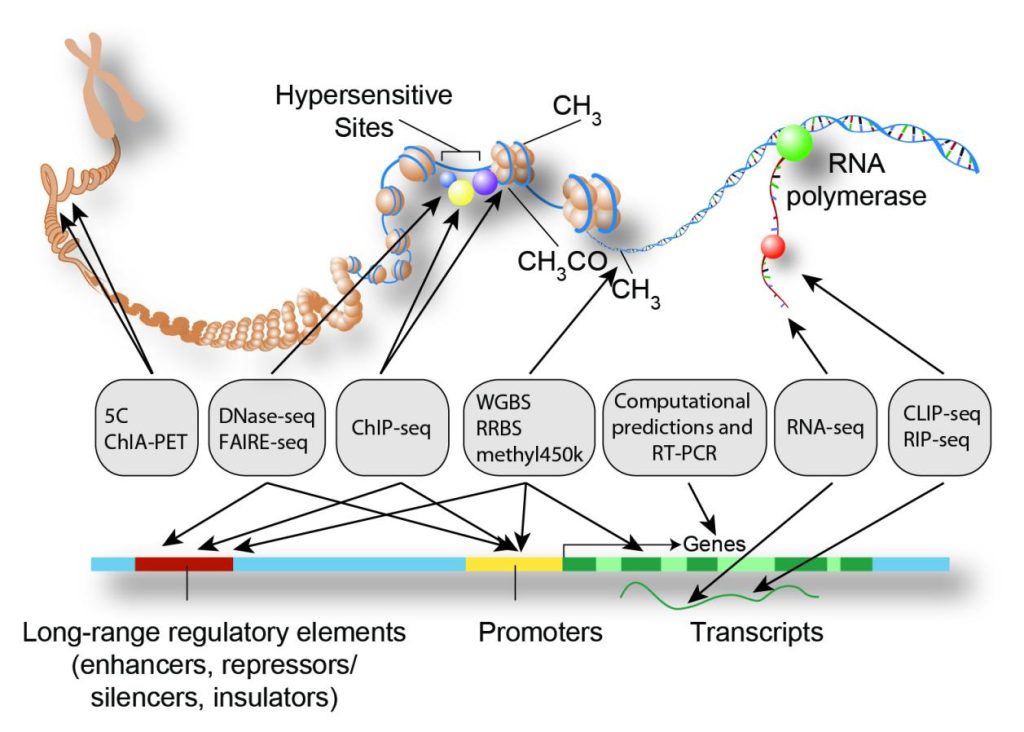

Focused ultrasonication has a deep track record across next-generation sequencing (NGS), chromatin biology, and microbial ID pipelines. It is a mainstay for DNA fragmentation in library construction and for chromatin shearing in ChIP-Seq and related assays.

•Investigators such as Elaine R. Mardis (Washington University Genome Center) and Jay Shendure (University of Washington) have detailed closed-tube acoustic shearing protocols for NGS libraries, emphasizing tight fragment distributions, low sample loss, and improved reproducibility compared with probe-based methods.

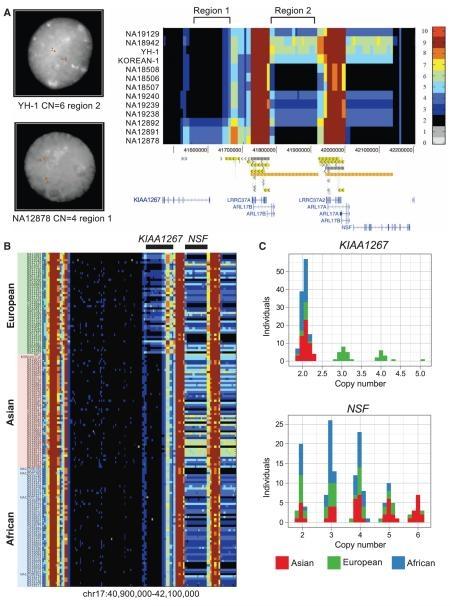

(Elaine R. Mardis and Jay Shendure, 2010,Diversity of human copy number variation and multicopy genes)

•High-throughput teams, including the Broad Institute and the ENCODE Consortium, describe sonication-based DNA fragmentation and chromatin disruption in published methods, underscoring broad acceptance of focused acoustics in scaled, regulated environments.

(About ENCODE Data at UCSC)

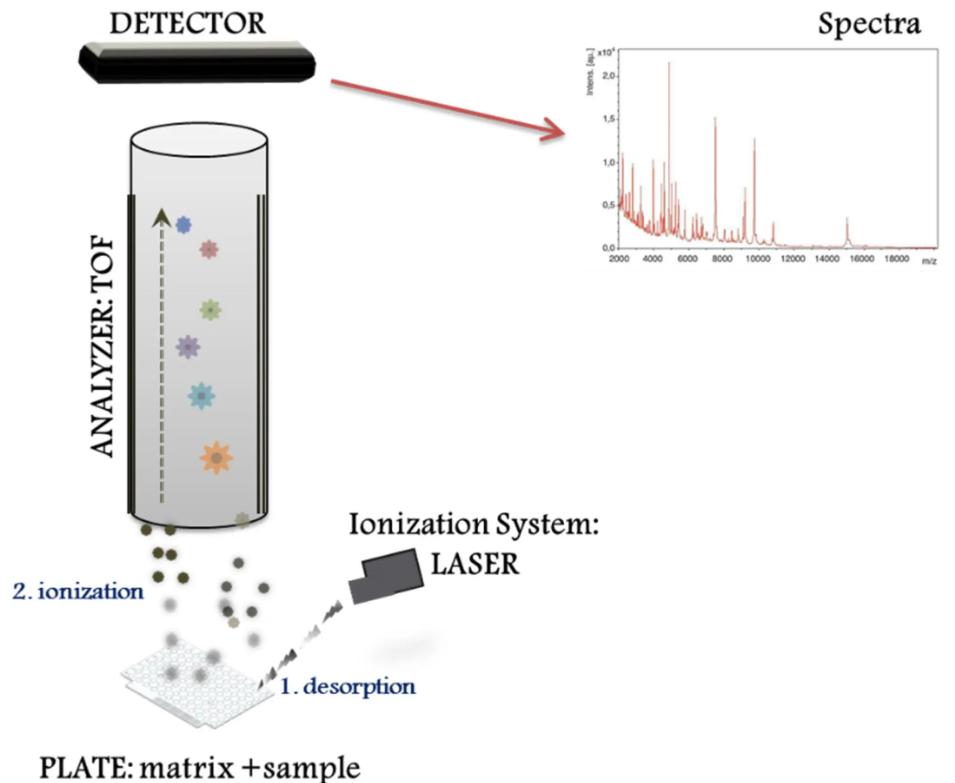

•Clinical microbiology teams adopting MALDI-TOF MS depend on optimized ultrasonication to break down resilient organisms – filamentous fungi, Mycobacterium – delivering uniform lysates that increase spectral signal-to-noise and raise identification accuracy.

(MALDI-TOF MS Mycobacterium Speciation | Test Price In Delhi | Ganesh Diagnostic)

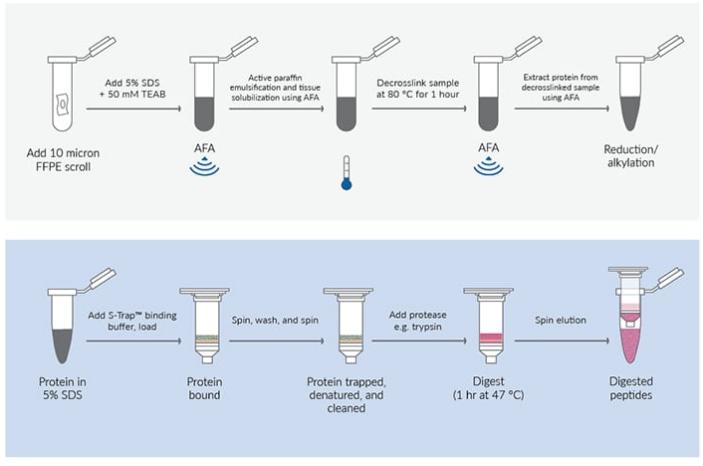

•Histopathology labs increasingly use focused acoustics to deparaffinize FFPE sections and recover nucleic acids under low-temperature conditions, maintaining integrity for PCR, sequencing, and protein profiling.

(FFPE Extraction | Covaris)

Taken together, these examples show how an Ultrasonicator for DNA Extraction enables standardized, traceable methods across multi-site programs while lowering manual variability and cross-operator drift.

Longlight‘s One–Stop Ultrasonicator: Design and Advantages

The Ultrasonicator for DNA Extraction is designed to release DNA efficiently without unintended over-fragmentation. Fragmentation is applied only when explicitly required by the workflow. As a manufacturer, Longlight Technology designs for one outcome: reproducible data from complex samples with minimal operator effort. Our one–stop Ultrasonicator for DNA Extraction combines multi-channel throughput, active temperature management, and full data traceability in a compact, bench-friendly system designed for daily use.

Flexible throughput begins with 16 well positions. Process a single critical sample or a full rack of 16 in one session. Each position can run an independent acoustic profile – duty cycle, power density, total exposure – so you can tailor settings to sample composition. For routine matrices, a batch mode lets you enter parameters once and execute one-click processing across all like samples, reducing set-up time and error.

•Noncontact processing: Ultrasound is coupled through a fluid path without direct sample contact, minimizing cross-contamination, aerosol formation, and carryover.

•Stable low-temperature, isothermal control: High-precision sensing and closed-loop feedback keep a tight thermal envelope, preserving DNA integrity and limiting heat-induced bias during shearing or lysis.

•Quiet operation: Acoustic noise reduction engineering removes the requirement for oversized sound enclosures, ideal for shared cores and typical bench setups.

•End-to-end traceability: Automatic capture of run parameters, time stamps, and data outputs supports audits, training programs, and cross-group method confirmation.

•Automatic drainage: Automated waste purge at a touch, with level sensing and early overflow notices, lowers maintenance burden and limits exposure.

•Integrated OS: Embedded OS obviates external PCs, shrinking the setup and enabling rapid deployment in constrained lab areas.

A confocal scheme directs energy precisely, suppressing losses into the coupling medium and giving tighter control of exposure. Units are factory-calibrated against references to deliver uniform performance – critical for multi-site studies and regulated workflows that demand comparability.

Applications and Industry Pain Points We Solve

Complex samples can quickly reveal the limits of older sonication approaches. Probe systems can introduce contaminants, create aerosols, and deliver energy unevenly from tube to tube. Generic water baths may heat samples unpredictably, resulting in biased fragment distributions or over-shearing. Throughput is another bottleneck: labs frequently choose between single-tube precision and batch efficiency.

An Ultrasonicator for DNA Extraction from Longlight Technology addresses these constraints with precise, noncontact acoustics; independent channels for per-sample tuning; and fully traceable runs.

•Genome fragmentation in NGS: Produce tight, targetable fragment distributions – even from high-MW gDNA – to boost library complexity and lessen size-selection demands.

•Chromatin fragmentation and cell/tissue lysis: Apply rigorous thermal control during lysis and fragmentation to safeguard epitopes and stabilize protein – DNA complexes for downstream omics profiling.

•FFPE deparaffinization: Low-heat paraffin removal that improves nucleic acid and protein integrity for sequencing and immunoassay applications.

•MALDI-TOF MS preparation: Standardize lysis workflows for filamentous fungi and Mycobacterium to sharpen mass spectra and boost confidence in species-level calls.

•Homogenization of biological tissue: Produce uniform suspensions without direct mechanical contact, enabling cleaner RNA/DNA extraction and proteomics with fewer artifacts.

Traceability and safety come standard. Run metadata and outcomes are captured for audit trails. Auto-drain and overflow detection streamline compliance, reduce operator touch time, and keep benches tidy. Low-noise operation fits shared environments without extra enclosures or infrastructure.

Implementation, Quality Assurance, and Call to Action

Deploying our one-stop Ultrasonicator for DNA Extraction is straightforward. Kick off with a pilot that matches your sample mix, including viscous, low-biomass, or FFPE material. Use per-well adjustments for outliers and batch mode for routine sets. Validate with your QC standards – microfluidic sizing, capillary electrophoresis, or qPCR yield – to verify fragment profiles and recovery. Then lock in method templates so future runs are one-click, fully traceable, and consistent across operators and shifts.

- Key Capabilities for Complex Samples

•Process 1 – 16 samples per session; mix custom per-well profiles with batch profiles as needed.

•Maintain a tightly controlled, isothermal environment with high-sensitivity sensors to protect DNA quality.

•Operate quietly in standard lab space; no external PC or sound enclosure required.

•Retrieve complete run data and audit trails to support training, reproducibility tracking, and compliance.

Start With a Pilot

We recommend a short feasibility study using your typical specimens – viscous matrices, low-input samples, or FFPE sections – so our applications team can map acoustic settings to your targets. This reduces time-to-validation, accelerates SOP creation, and eases transfer into regulated or high-throughput operations.

Longlight Technology provides the instrumentation, protocols, and support to make complex sample preparation predictable and repeatable. Our Ultrasonicator for DNA Extraction delivers noncontact processing, true low-temperature control, quiet operation, traceable workflows, and both batch and custom runs – augmented by automatic drainage and an integrated operating system.

Call to Action

Ready to standardize your DNA workflows? Email Longlight Technology to request a demo, submit test samples for qualification, or arrange a protocol consultation. Equip your team with a one-stop Ultrasonicator for DNA Extraction crafted for complex samples and reliable reproducibility.