Related Post

Safety Tips for Operating Vacuum Centrifugal Concentrator Laboratory Equipment

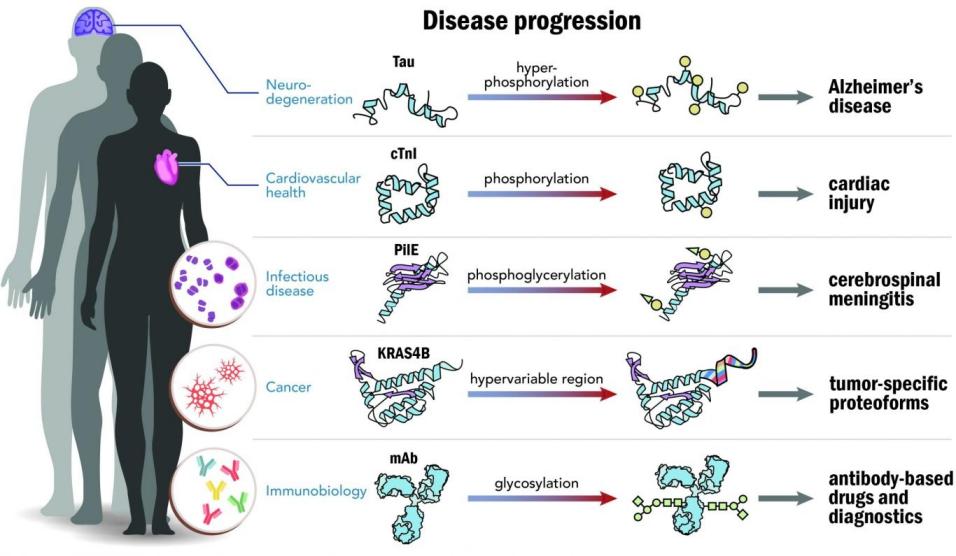

2025-09-22Vacuum Centrifugal Concentrator Laboratory Equipment sits at the center of modern sample prep , and at Longlight Technology we see one truth: safe, disciplined operation is the fastest path to trustworthy data and smooth laboratory workflows. Vacuum centrifugal concentrators (e.g., SpeedVac) are cornerstone lab tools that evaporate solvents gently under vacuum with centrifugal force, minimizing sample loss. They have supported internationally renowned research in genomics and proteomics, from the Human Genome and Human Proteome Projects to clinical biomarker discovery studies. By rapidly concentrating DNA/RNA eluates, peptide digests, metabolites, and small-molecule fractions, these instruments streamline high-throughput workflows.

(The Human Proteoform Project: Defining the human proteome – Northwestern Proteomics)

Key application areas: genomics (nucleic-acid cleanup), proteomics/peptidomics, metabolomics/lipidomics, microbiology, environmental analysis, pharmaceutical discovery/ADME, food-safety testing, and biochemistry sample prep before LC-MS/GC-MS/NMR. Low-temperature operation protects volatile analytes and labile post-translational modifications while boosting sensitivity and reproducibility across analytical platforms.

Why Safe Use of Vacuum Centrifugal Concentrator Laboratory Equipment Matters

In genomics, proteomics, and analytical testing, small handling errors can undo hours of bench work. A mis-set temperature can degrade DNA/RNA. A poor seal can let vapors escape and contaminate neighboring samples. Imbalanced loads can shake an instrument, shorten its life, and scatter precious material. Used correctly, Vacuum Centrifugal Concentrator Laboratory Equipment protects heat-sensitive targets by removing solvents under reduced pressure with controlled heat. Used casually, it can introduce variability you do not want – especially when scaling Next-Generation Sequencing (NGS) or supporting time-critical drug development.

At Longlight Technology, we design for safety first because that is where consistency begins. Our customers tell us their biggest pain points are rework, sample loss, instrument downtime, and training gaps between shifts. Addressing those issues starts with clear practices and hardware that helps operators do the right thing by default.

✅ Hidden Risks in Routine Concentration

- Residual solvent carryover that skews downstream quantitation

- Overheating that harms oligonucleotides, proteins, or enzymes

- Rotor imbalance that raises vibration and wear

- Corrosion from aggressive organic solvents that costs time and money

Field-Tested Safety Tips from Longlight Technology

Teams ask us for a simple playbook they can adopt in minutes. Below are steps we recommend for safe, repeatable use of Vacuum Centrifugal Concentrator Laboratory Equipment. Keep the language in your SOP simple. Make the checks visual. Consistency is the real safety feature.

✅ Before You Start

- Match rotors and adapters to tube formats. Use the correct inserts for 1.5 mL and other sizes to preserve balance and recovery.

- Load symmetrically. Mirror each tube across the rotor to minimize vibration and protect bearings during high-throughput runs.

- Inspect the seal and pressure path. Clean the gasket, ensure the lid sits flat, and confirm the pressure-relief channel is unobstructed.

- Confirm program parameters. Gentle temperature setpoints and proper ramping protect heat-sensitive samples; two-stage temperature control helps you start cool and finish efficiently.

- Note your solvents. Anti-corrosion features are robust, but it still pays to record which aggressive organics are present so you can plan cleaning and storage.

✅ During and After Each Run

- Watch vacuum and temperature on the digital gauges. An anti-corrosion vacuum gauge remains readable around organic vapors – use it to spot anomalies early.

- Allow automatic pressure release. Let the pressure relief valve do its work to avoid sudden pressure shocks at the end of a cycle.

- Cool down before opening. Gentle temperature recovery protects targets and improves yield.

- Wipe residues right away. A 304 stainless-steel cavity with a Teflon coating resists solvents; quick cleaning keeps it that way.

- Document the recipe. With four shortcut keys and memory for up to 30 user programs, lock in what works so results are reproducible across shifts.

Built-In Safeguards That Make Safety Easier

We engineer Vacuum Centrifugal Concentrator Laboratory Equipment so safety is the path of least resistance. The fast control system delivers intelligent, precise, and efficient operation with a friendly interface that keeps training simple. An electromagnetic drive provides high throughput with low vibration, enabling concentration of ninety 1.5 mL tubes at once while protecting both samples and hardware. Stability is not a luxury here – it is how you maintain data integrity and instrument health.

Materials and vacuum path. Real labs use real solvents. That is why we build with a 304 stainless-steel cavity and Teflon coating, and apply anti-corrosion treatment to the entire machine. The built-in diaphragm vacuum pump features a pure PTFE (Teflon) pump head that is completely resistant to chemical corrosion, so you can process challenging matrices with confidence. The digital anti-corrosion vacuum gauge remains stable and readable even in organic vapor environments, providing a clear window into the pressure profile throughout the run.

Control and programmability. Two-stage temperature control prevents thermal spikes that threaten sensitive biomolecules. The automatic pressure relief valve vents vacuum smoothly at the end of a cycle, and automatic switching reduces steps that can trip up new users. Rich accessories – rotors and adapters for many tube sizes, plus optional cold-trap configurations – let you tailor the setup to DNA/RNA, oligonucleotides, proteins, and other liquid samples without improvisation. For teams building capacity in NGS and analytical testing, the programmable control system and intuitive digital display make training straightforward. You can add concentration imaging to monitor runs with greater transparency, improving both safety and efficiency.

Throughput without shortcuts. High productivity and safe operation are not opposites. When loads are balanced and seals are clean, the drive stays quiet, temperatures stay on target, and methods are repeatable. That is the behavior we design for – fast enough for busy cores, gentle enough for heat-sensitive targets, and clear enough for technicians to teach one another.

Training and scale-up. Many incidents trace back to inconsistent operator habits. Store validated methods with the four program shortcuts and 30-program memory, post a one-page SOP near the instrument, and use the on-screen prompts as your training script. When the tool guides the workflow, onboarding is faster and safer.

✅ Quick Checklist for Busy Teams

- Use stored programs for fewer setup mistakes

- Verify balance and lid seal before every run

- Let automatic vacuum release finish before opening

- Clean the coated cavity after solvent-heavy runs

In practice, these design choices and habits work together. Operators spend less time troubleshooting. Samples recover better. Maintenance intervals stretch out. Most importantly, downstream assays behave as expected – because the concentration step is consistent and gentle.

Call-to-Action

If you want to raise safety and throughput without adding complexity, talk to Longlight Technology. We can help you configure Vacuum Centrifugal Concentrator Laboratory Equipment for your specific solvent set and tube formats, map “best practices for vacuum sample concentration” into your SOPs, and train your team. Request a consultation or on-site demo, and turn safe operation into your lab’s everyday advantage.