Related Post

How High Reproducibility Sonicator Fixes Batch-to-Batch Variations

2025-12-23A High Reproducibility Sonicator is a focused ultrasonication platform that treats samples without direct contact, under stable temperature control, to ensure results stay the same from batch to batch. Today, many leading genomics and proteomics labs rely on this technology for DNA shearing in next-generation sequencing, difficult cell and tissue lysis, and FFPE sample preparation. It is also widely used in MALDI-TOF MS workflows for hard-to-break microorganisms. Why do so many high-throughput and clinical research labs trust this type of sonicator for critical projects? And how exactly does it reduce batch-to-batch variations instead of adding more noise? We will explore that in the sections below.

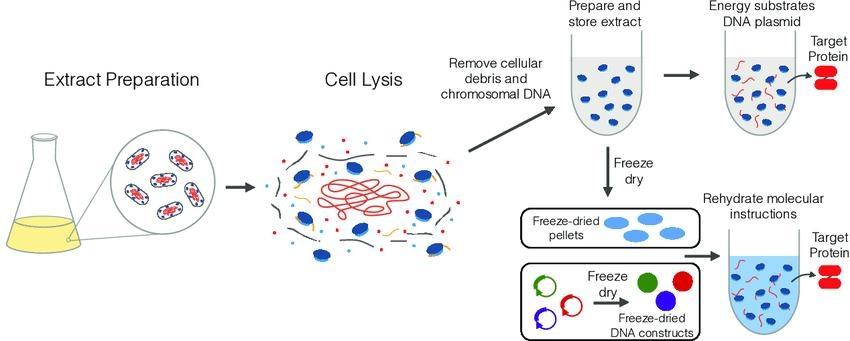

(Overview of Cell Lysis and Protein Extraction – Creative Proteomics)

Why Batch-to-Batch Variations Hurt More Than You Think

Most scientists accept a certain level of variation as “normal.” But when you look closely at where projects get delayed, batch-to-batch differences come up again and again.

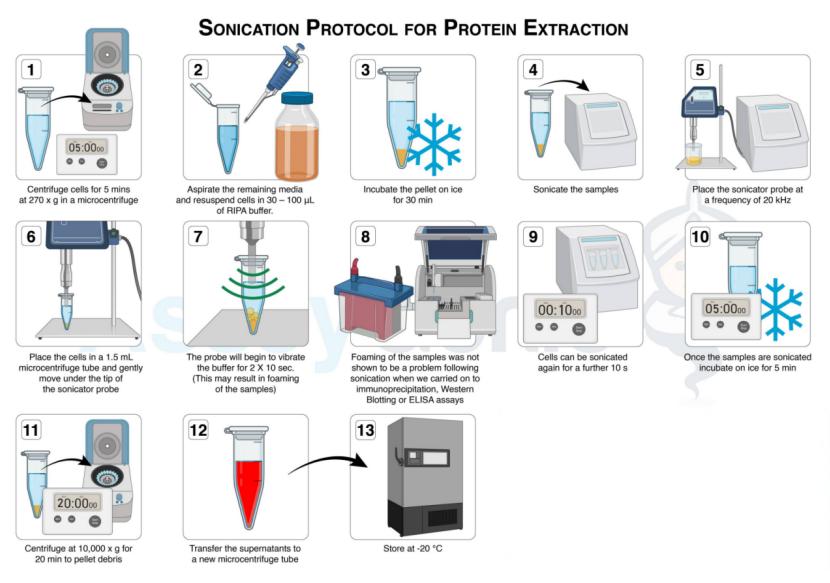

In sequencing labs, a slight change in DNA fragmentation affects library size profiles and QC pass rates. In proteomics or MALDI-TOF MS workflows, small differences in lysis or homogenization can shift peak patterns. In clinical or industrial labs, inconsistent prep makes it harder to compare results across runs, sites, or operators.

A lot of this noise starts at the sample prep stage:

✅Subtle differences in manual handling between operators

✅Uneven energy delivery from classic probe-based sonicators

✅Temperature drifting during long ultrasonic runs

✅Direct contact between probe and sample increasing contamination risk

When fragmentation, lysis or homogenization is not uniform, you may see failed libraries, poor protein yield, or unstable spectra. Teams then spend days troubleshooting, repeating batches, and arguing about whether the “problem” is the biology or the equipment.

The idea behind a High Reproducibility Sonicator is simple: remove as many of those weak points as possible. Instead of relying on operator experience and open water baths, the system uses focused ultrasound energy, controlled conditions and detailed logging to apply the same treatment every single time.

How a High Reproducibility Sonicator Puts You Back in Control

At the heart of a High Reproducibility Sonicator is focused ultrasound technology. High-frequency, short-wavelength sound waves are precisely directed to the sample area, rather than being sprayed into the bath and hoping enough energy reaches the tube. The energy travels through an acoustic medium in a managed water environment, not through a metal probe tip touching your sample.

That design change drives several practical benefits.

- Non-Contact Processing for Cleaner, Fairer Results

Traditional probe systems dip the tip directly into the sample. This is simple, but it comes with a price: potential cross-contamination, inconsistent tip positioning, and hot spots where energy is concentrated.

A focused, non-contact system does it differently:

✅Ultrasonic energy passes through the water bath to a closed sample tube

✅The probe never touches the sample, lowering contamination risk

✅Each sample position is designed to receive comparable energy

For precious DNA, RNA and protein samples, that matters. What you see downstream is far more likely to be driven by the biology of the sample, not by whether a probe was inserted 1 mm deeper or cleaned a little less thoroughly between runs.

- True Temperature Control, Not Just “Cold Enough”

Anyone who has watched an ultrasonic bath knows how quickly temperature can creep up. Overheating can damage nucleic acids, denature proteins, and push enzymes out of their optimal range – all invisible sources of batch-to-batch variation.

A High Reproducibility Sonicator integrates a sensitive temperature sensing and control system. The sample region is kept at low and constant temperature, and the system actively monitors and adjusts conditions during the entire process.

This brings you:

✅Better protection for temperature-sensitive DNA, RNA and proteins

✅More stable performance in workflows that rely on enzymes

✅Less drift between early and late samples in a long batch

Instead of improvising with ice, timers or constant manual checks, temperature management becomes part of the instrument’s job.

- Flexible Throughput and Traceable Runs

Modern labs rarely have the luxury of one sample type at a time. One batch might be DNA fragmentation for NGS; the next could be FFPE tissue, tough microorganisms, or mixed tissue samples. A High Reproducibility Sonicator is designed to handle this reality.

You can run in a flexible mode and process anywhere from a single tube up to a small batch in one session. Each sample can have tailor-made ultrasonic conditions when needed, which is especially useful for complex or pilot studies. When you move into routine work, you switch to batch mode and apply the same parameters across many similar samples with a single setup.

Behind the scenes, the system records key processing information, so you can look back at which settings produced which results. This traceability is invaluable for troubleshooting, method transfer, and audits.

Add to that:

•Quiet operation that fits naturally into an open lab

•Automatic waste drainage with level monitoring and overflow warning

•A built-in operating system that removes the need for a dedicated PC

and you have a compact, self-contained tool that reduces clutter and friction in daily use.

Where a High Reproducibility Sonicator Makes the Biggest Difference

The power of a High Reproducibility Sonicator becomes obvious when you look at real workflows instead of just features on a spec sheet.

- From NGS to Proteomics: One Platform, Many Workflows

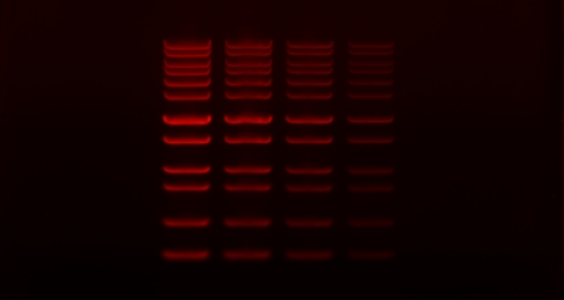

Focused ultrasonication is now a key technique for DNA shearing in next-generation sequencing. Precise and narrow fragment size distributions are essential for stable library performance. With controlled ultrasonic energy and tight temperature control, labs can hit those ranges more reliably and keep QC rejection rates under control.

The same platform can also support a wide range of other tasks:

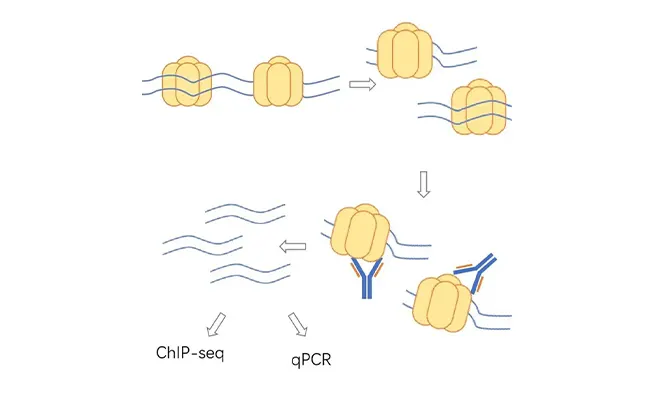

✅Genome fragmentation and sample prep for genomics and proteomics

✅Cell and tissue disruption for DNA, RNA or protein extraction

✅Lysis of filamentous fungi and Mycobacteria before MALDI-TOF MS

✅Fragmentation and homogenization of soft and hard biological tissues

✅Deparaffinization of FFPE samples before downstream analysis

(Complete Sonication Protocol for Cell Lysis | Step-by-Step Guide + Expert Tips)

The shared pain point across all these workflows is reproducibility. You need samples prepared today to behave like samples prepared weeks or months from now, even if staff change and throughput increases. A High Reproducibility Sonicator is built to deliver that consistency as part of the system, not as an add-on responsibility for your team.

Turn Reliable Sample Prep into a Competitive Advantage (CTA)

Labs that can stand behind their data with confidence win more projects, keep more partners, and spend less time re-running old work. Standardized, reproducible sample preparation is a big part of that story.

If your team is still wrestling with:

- Fragmentation profiles that shift from run to run

- Extraction yields that refuse to stay stable

- Temperatures that quietly climb during sonication

- High repeat rates and failed QC batches

then it may be time to rethink the core of your ultrasonic workflow.

A High Reproducibility Sonicator offers a controlled, scalable and traceable way to prepare samples for NGS, proteomics, MALDI-TOF MS and more. It helps you say goodbye to batch-to-batch variations and build workflows that are robust enough to grow with your lab.

If you are planning your next platform upgrade or setting up a new lab, consider making a High Reproducibility Sonicator from Longlight Technology part of your standard toolkit. It turns sample preparation from a daily risk into a reliable foundation for every experiment that follows.