Related Post

Magnetic Bead Separators: Trim Raw Material Loss at Scale | 2026 Guide

2026-01-13Magnetic Bead Separators are redefining how labs and manufacturers reduce process loss at scale while upholding quality and protecting operators. At Longlight Technology, we design systems that convert this promise into consistent, repeatable results. This guide presents the essentials, showcases pivotal studies, and explains how our MSG series ensures uniform fields, safe use, QA adherence, and dependable scale-up across nucleic acid, protein, and cell workflows.

(Magnetic cell separation | Miltenyi Biotec | Deutschland)

What Are Magnetic Bead Separators and Why They Matter

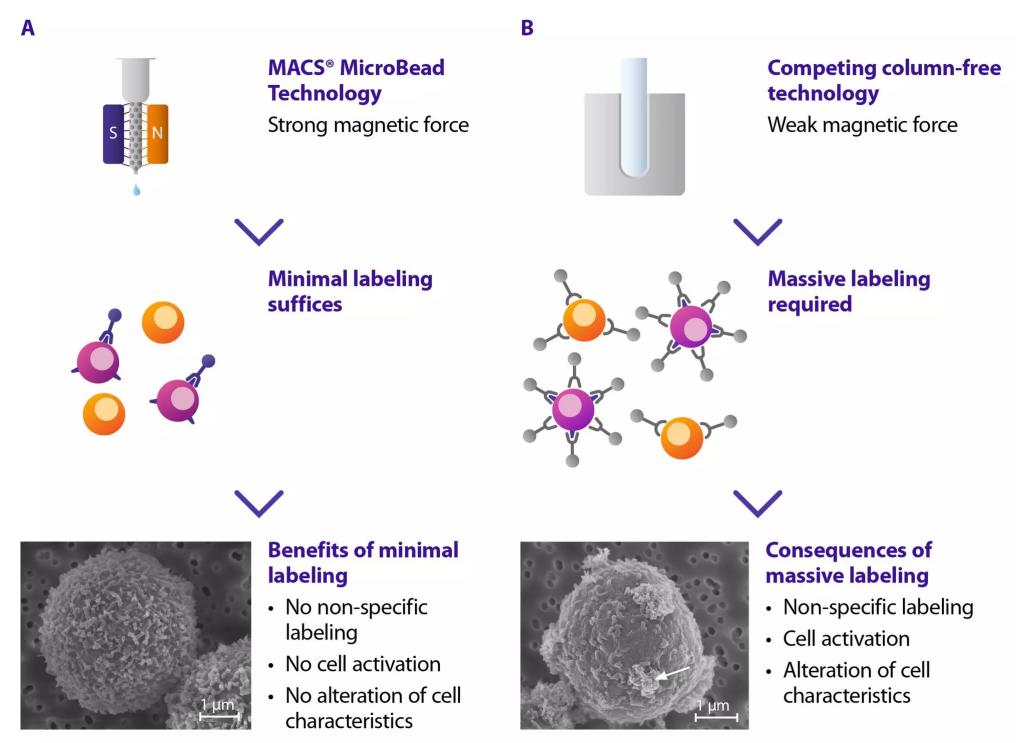

Magnetic Bead Separators use precisely controlled magnetic fields to hold paramagnetic beads that bind to targets including DNA, proteins, and cells. It reduces the need for centrifugation and filtration. The approach matured over decades of research and engineering. Oddvar Ugelstad pioneered monodisperse polymer beads that became the basis of widely used magnetic microbeads for immunoassays and separations. Stefan Miltenyi introduced magnetic-activated cell separation, which standardized positive and negative cell selection with high purity. Clinical translation then accelerated. Carl June and his collaborators progressed CAR-T therapy, relying on bead-centric enrichment and activation steps in manufacturing. During the COVID-19 response, magnetic bead nucleic acid extraction scaled quickly, enabling high-throughput PCR and isothermal assays worldwide.

(MACS® MicroBeads for magnetic cell isolation | Miltenyi Biotec | Deutschland)

They are driven by the same underlying technology. Reliable magnetic fields and consistent bead behavior determine yield, purity, and throughput. When fields are uneven, beads aggregate, and valuable reagents are lost. When forces are tuned and uniform, capture is efficient, and elution is clean. This is the core design logic behind Longlight’s systems for production use.

Scale-Up Without Waste: Industry Pain Points and Pathways

Translating a 1 mL protocol into several liters per batch is not a linear task. Teams navigate mechanical, magnetic, and operational barriers that cause raw material loss and rework.

• Non-uniform magnetic fields cause dead zones and hotspots. Beads drift or cluster, lowering capture efficiency and increasing carryover.

• High-shear mixing and repeated centrifugation add stress and handling. Sensitive proteins denature. Cells lose viability. Nucleic acids shear.

• Large permanent magnets entail pinch risks and stray-field exposure. Safety cages and barriers are needed for install and day-to-day use.

• No in-process monitoring: deviations surface post-batch, increasing scrap and the scope of investigations.

• Scale-up transforms vessel geometry, residence time, and force balance; workflows tuned for 15 mL often fall short at 10 L unless field and kinetics are re-optimized.

• QA compliance mandates reproducibility, traceability, and validated control limits. Manual interventions increase variability.

Addressing these issues requires systems that deliver uniform fields across the entire working area, real-time visibility into the separation, and safe mechanical design. It also requires a clean path to validation, with documented performance from milliliters to tens of liters. The result should be simple: fewer handling steps, lower bead and reagent consumption, and consistent recovery.

Inside the Longlight MSG Series

Longlight Technology designs Magnetic Bead Separators for production teams who need economical, high-throughput separation with minimal loss. Our MSG series covers batch workflows from milliliter-scale prototyping to tens of liters in production, with made-to-order volume options that fit your footprint. The architecture aligns around uniform fields, operator safety, and integrated monitoring.

• Uniform Magnetic Fields: A carefully regulated working area sustains a steady, homogeneous field so beads encounter the same forces everywhere. This curtails aggregation, reduces sediment formation pockets, and improves elution efficiency.

• Safer handling is realized during setup, cleaning, and changeover.

• Real-Time Monitoring: Continuous real-time monitoring of the separation phase. Operators can quickly tune timing and agitation to avert under-capture or compaction, supporting reproducibility.

• Excellent Bead Capture Efficiency: Per-step, per-scale parameter tuning elevates capture efficiency.

• Centrifuge-Free Workflow: The process operates without centrifugation. One-step protocols shorten cycles, reduce touchpoints, and limit shear forces.

• Customizable Volumes: Configurations are available for development through manufacturing. Teams can scale from small batches to several liters per batch and onward to tens of liters without replatforming.

These elements combine to trim raw material loss. Uniform fields protect bead integrity. Safe ops reduce downtime and incidents. Monitoring closes the loop on process drift. The net effect is lower consumption per batch, higher recovery, and stronger lot-to-lot consistency.

Applications Across NA, Protein, and Cell Workflows

Magnetic Bead Separators are integral to biomolecular manufacturing. The MSG series accommodates diverse targets while prioritizing yield, purity, and robust process control.

- Nucleic Acids

Extraction and cleanup depend on reproducible bead kinetics and clean releases. Bead-based extraction sustained high-throughput COVID-19 pipelines with strong yields. Uniform fields in production vessels make binding and elution consistent run-to-run. Real-time monitoring guides timing for bind, wash, and release. By avoiding centrifugation, shear on long fragments is lowered and automated cycles are faster. Efficient workflows support plasmids, AAV/viral vectors, and assay-grade nucleic acids.

- Proteins

Protein processes must remain gentle to maintain activity. Aggregation or overcompaction can sequester target and raise losses. With uniform fields, beads form stable, even layers for controlled washes and sharp elutions. The MSG series supports tuning of residence time and mixing, helping ligands reach capacity without overexposure. Applicable to antibody capture, enzyme recovery, and biocatalysis where activity retention and throughput are equally important.

- Cells

Cell selections depend on viability, phenotype integrity, and high-specificity capture. Magnetic selection is integral to processes inspired by Miltenyi’s work and used across immunotherapy and research. For CAR-T workflows, established clinically by Carl June and contemporaries, magnetic beads enrich and activate cells before genetic modification and expansion. Gentle, centrifuge-free separations help preserve viability. Uniform fields reduce clumping and promote even exposure. Safe operations protect personnel around large magnets during set-up and changeovers.

Beyond these core areas, the MSG series supports single-cell proteomics, synthetic biology, and diagnostic reagent development. Consistent field strength and monitored separations increase reproducibility, facilitating method transfer across sites and scales.

From mL to Tens of Liters: QA-Ready Scale-Up with Magnetic Bead Separators

Scale-up is more than bigger hardware. It is a controlled translation that sustains kinetics, forces, and mixing under new geometries. Longlight’s design philosophy preserves field uniformity as volume increases, so beads behave the same way at 5 mL, 5 L, or tens of liters. This reduces the re-optimization burden and lowers risk.

Process monitoring supports robust quality systems. Continuous monitoring provides complete records for deviation analysis and trend evaluation. Qualified limits around separation duration and mixing parameters align with validation norms. Teams run installation and operational checks, then qualify performance against documented acceptance criteria. Removing centrifugation steps lowers operator touch time and variability, helping batch records and investigations.

The impact on raw material loss is direct. Fewer beads are wasted due to aggregation or uneven capture. Wash volumes are optimized. Elution is clean. Operators work safely and consistently. Batch cycle times shorten, increasing throughput without compromising yield.

Call to Action

If your team intends to scale Magnetic Bead Separators from pilot studies to several-liter production batches and beyond, we can help. Longlight Technology provides systems that deliver uniform fields, safe operations, real-time monitoring, and customization to your volumes. Contact us to discuss your nucleic acid, protein, or cell workflow. Request an application review, a process demo, or a scale-up plan aligned with your QA requirements. Reduce raw material loss at scale with a platform built for modern bioprocessing.