Related Post

What Makes Protein Purification Magnetic Separator Quicker Than Columns?

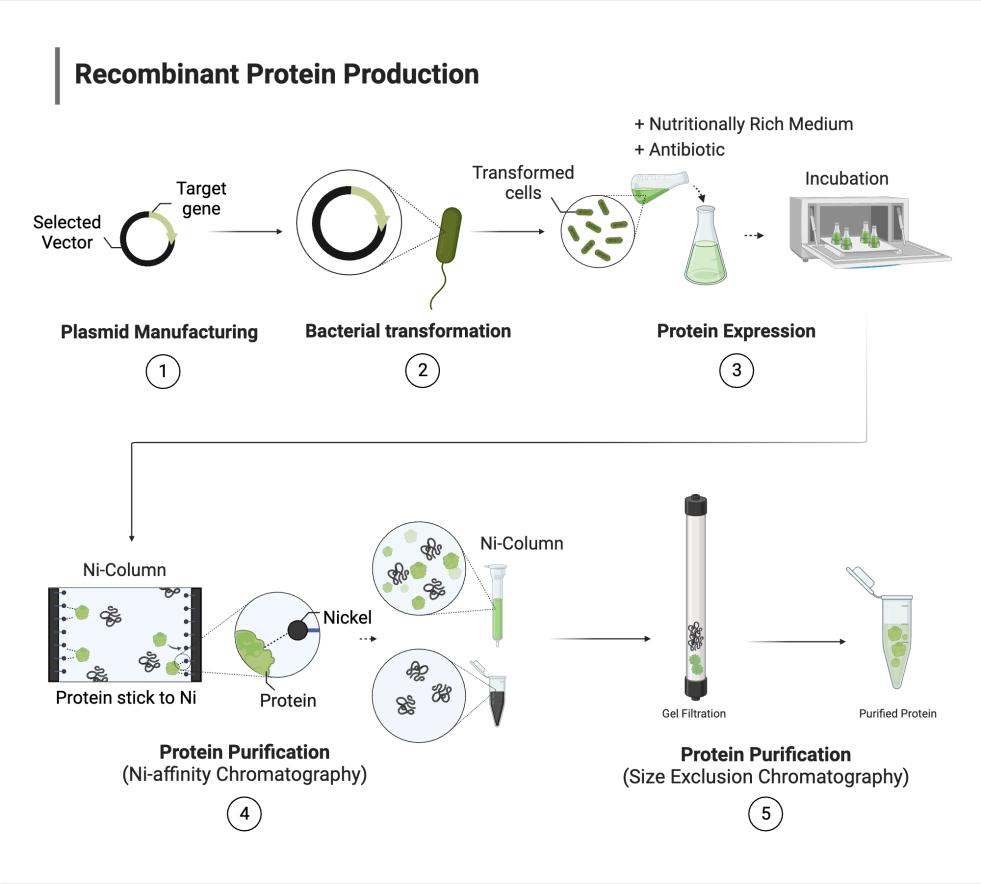

2025-12-16A Protein Purification Magnetic Separator uses magnetic beads instead of a packed column bed. The beads bind target proteins directly in the liquid. A magnetic field then pulls them out in one clean step. No fragile resin. No blocked flow path. This technology is now common in recombinant protein production, vaccine development, and high-throughput diagnostic kit manufacturing. Many research groups use it for antibody purification, cell surface protein studies, and nucleic acid clean-up in omics projects. Leading biopharma labs and automation platforms have already built workflows around magnetic separation. Yet most teams still ask the same question: if the principle is so simple, why is it so much faster than conventional columns?

(Recombinant Protein Production | BioRender Science Templates)

Why Traditional Columns Struggle as You Scale

Chromatography columns have earned their place in the lab. They’re familiar, documented in countless SOPs, and often already validated for GMP environments. Once you move beyond small test volumes into multi-liter batches, those limitations start to take over the day.

Columns that were fine at bench scale suddenly become a major constraint:

•Extended equilibration, wash, and regeneration phases

•Sensitivity to viscous or contaminated samples that disturb flow

•Ongoing manual adjustments to pressure, valves, and gradients

This quickly turns into:

•Longer processing times per batch

•More staff locked into low-value column operations

•A higher chance of errors and failed runs

As throughput demands rise, a system that needs continuous attention no longer makes sense.

How a Protein Purification Magnetic Separator Changes the Game

A Protein Purification Magnetic Separator takes a different route. Magnetic beads replace the packed bed as the solid phase. Instead of pushing sample through a column, you mix beads directly with the liquid, allow your target proteins to bind, and then use a magnetic field to pull the beads to the side or bottom of the vessel.

No fragile bed to pack. No flow path to clog. No wrestling with backpressure.

The core principle is simple:

•Mix beads and sample

•Bind target molecules

•Capture beads with a magnetic field

•Remove supernatant, wash, and elute

That physical simplicity is a big part of why a Protein Purification Magnetic Separator can deliver shorter cycles at scale.

What Actually Makes Protein Purification Magnetic Separator Faster?

A modern Protein Purification Magnetic Separator is not just a magnet taped to a bottle. It is a purpose-built system for batch-based processing of proteins, nucleic acids, and cells. The design of the magnetic field, vessel, and controls all contribute to speed and consistency.

- Uniform Magnetic Field, Predictable Bead Behavior

In improvised setups, the field can be strong but uneven. Beads slam into one corner, form dense clumps, and become difficult to wash or elute efficiently. A well-designed Protein Purification Magnetic Separator generates a uniform, stable field across the working volume so that:

•Beads in every region feel a similar magnetic force

•Aggregation is reduced, improving washing and elution

•Bead and product loss are minimized over many cycles

Because bead movement is predictable, you can optimize mixing and capture times instead of over-buffering “just in case.” In practice, this leads to faster separations, more stable yields, and less batch-to-batch variability.

- Built for Scale-Up, Not Just Bench Experiments

Most teams start with small-scale tests in tubes, plates, or shake flasks. The real stress test comes when you need to handle liters or tens of liters without redesigning your entire process.

A Protein Purification Magnetic Separator is designed with that jump in mind:

•The same core separation principle applies from milliliters to multi-liter batches

•Working volumes can be matched to your existing batch sizes

•Protocols scale mainly by adjusting volumes and timings, not by rewriting the workflow

That continuity simplifies tech transfer from R&D to pilot and production. Instead of developing a “column version” and a separate “manufacturing version,” you keep one magnetic separation strategy and adjust it as volumes grow. This can shorten validation timelines and reduce surprises when you reach GMP manufacturing.

- Data-Driven Separation Instead of Guesswork

Another advantage of a dedicated Protein Purification Magnetic Separator platform is the ability to build in real-time monitoring and smart control. In modern biomagnetic setups, integrated sensors and software watch the process through binding, washing, and elution.

This gives your team the ability to:

•Track separation status in real time instead of waiting for final test results

•Catch bead aggregation or incomplete capture before it becomes a deviation

•Adjust mixing speed, capture time, or wash cycles to keep yield and quality on target

Older column-based workflows depend on manual observation and pressure profiles, guided by operator intuition. While that expertise matters, it is difficult to standardize and nearly impossible to scale consistently between teams and sites. A more automated, data-driven Protein Purification Magnetic Separator workflow helps turn “tribal knowledge” into repeatable parameters and recipes.

(Novel Application of Magnetic Protein: Convenient One-Step Purification

and Immobilization of Proteins | Scientific Reports)

- Safer, Simpler Operation for Routine Work

For teams handling many runs each day, ergonomics and safety are not optional. A Protein Purification Magnetic Separator is typically housed in a protective enclosure that keeps strong magnets away from hands and tools. This design helps prevent pinched fingers and unexpected magnetic attraction to nearby hardware.

At the same time, bead-based protocols often:

•Reduce or eliminate repeated centrifugation steps

•Minimize manual sample transfers between tubes and columns

•Simplify buffer schemes and handling steps

Over months and years, that can translate into fewer ergonomic issues, less fatigue, and smoother day-to-day operation for the people running your purification line.

A Realistic Path From Columns to Magnetic Separation

Most labs cannot just switch off their columns overnight. The more practical approach is a phased transition, using a Protein Purification Magnetic Separator where it brings the most benefit first.

A good starting point is to analyze your current column process:

•Identify steps with the longest waiting or equilibration times

•Flag runs that frequently need rework due to pressure spikes or flow problems

•Map where bead or product loss is most painful for yield and cost

These high-friction steps are often the best candidates to replace with a magnetic separation stage. You can introduce a Protein Purification Magnetic Separator into a single part of the workflow while keeping the rest unchanged, then expand to more steps as confidence and internal expertise grow.

Once the new platform is integrated, daily work begins to look different:

•Fewer centrifugation and buffer-exchange steps

•Shorter total processing time per batch

•Less manual intervention during capture and washing

Because the same biomagnetic system can support protein purification, nucleic acid isolation, cell separations, biocatalysis, and diagnostic reagent preparation, many groups eventually standardize multiple workflows on one Protein Purification Magnetic Separator platform. That can simplify training, reduce the number of hardware types on site, and make long-term validation more straightforward.

Next Steps

If your column-based purification is struggling to keep up with current or planned throughput, this is a good moment to re-examine your setup. A Protein Purification Magnetic Separator can help you:

- Cut processing times without sacrificing quality

- Protect both magnetic beads and valuable samples

- Move more smoothly from milliliter-scale tests to liter-scale production

If you’re curious how this would look in your environment, start by mapping your current pain points and identifying one or two steps where a magnetic workflow could have the biggest impact. From there, you can evaluate a Protein Purification Magnetic Separator in a controlled way and begin taking the pressure off both your columns and your operators.